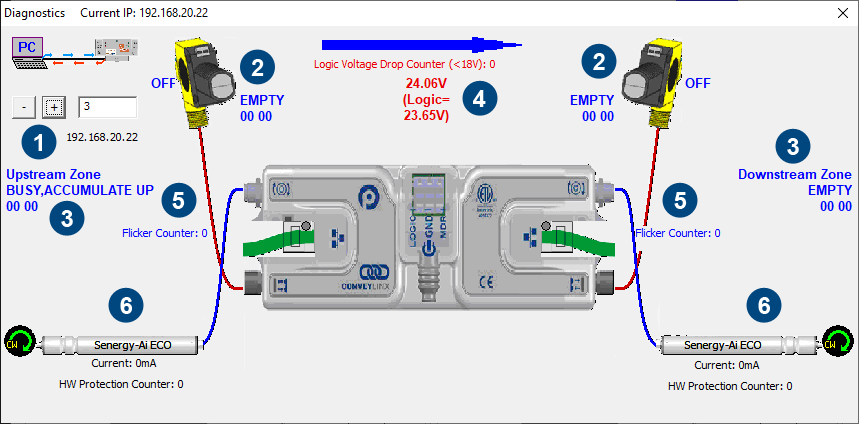

| Indicator | Description |

|---|---|

| You can navigate to the next or previous module’s Diagnostic Window by clicking the + and – buttons | |

| Displays the current ZPA status of the zone and the state of the sensor | |

| Displays the status of the upstream and downstream zones to the selected module. Note that the values depicted below the text (“00 00” in the example) indicate the contents of the Tracking Registers. | |

| Displays the current input voltage to the module as well as the count of the number of times the power supply went below 18 volts but did not completely shut off. This is useful for diagnosing possible power supply issues | |

| Displays current value of the sensor input’s Flicker Counter | |

| Displays current status of each motor. Please note that this data is also shown on the main screen as well |

Accumulation Status

If a carton is accumulated on a particular zone, the Diagnostic Window will indicate a reason for the accumulated state. Also note that in situations where an external device (PLC or PC controller) or the Accumulate icon on the Main Screen has been activated; the Sensor LED on the module for the stopped carton’s zone will be fast blinking green. You can then consult the Diagnostic Window for more detailed information on the exact reason

| As shown in this example, for the upstream zone on the selected Module, it shows “PLC” as the reason a carton is stopped at this zone even though its immediate downstream zone is empty |  |

Motor Roller Information

| One very useful feature of the Diagnostics window is that you can mouse-over the image of each roller and a pop-up will display the pertinent motor parameters as well as the part number and serial number of the connected roller as shown |  |

Flicker Counter

The Flicker Counter contains a running total of the number of state changes that have occurred during the Sensor Debounce time window. This can be used as diagnostic information to help you adjust the proper Sensor Debounce time for a given application