In this space, we will explore how to maximize the potential of this innovative 3D measurement tool for accurate and efficient results in your projects. Whether you are a seasoned professional or an enthusiastic beginner, here you will find useful tips, recommended techniques, and tricks of the trade that will help you master the use of Flexijet 3D.

Verification

- Step 1 of Verification: Connect corners as needed, and use Show Corners or Show CAD-Point to aim Flexijet at the corners for visual verification.

- Step 2 of Verification: Use the Dimension tools to place measurements on the page and verify with a tape measure.

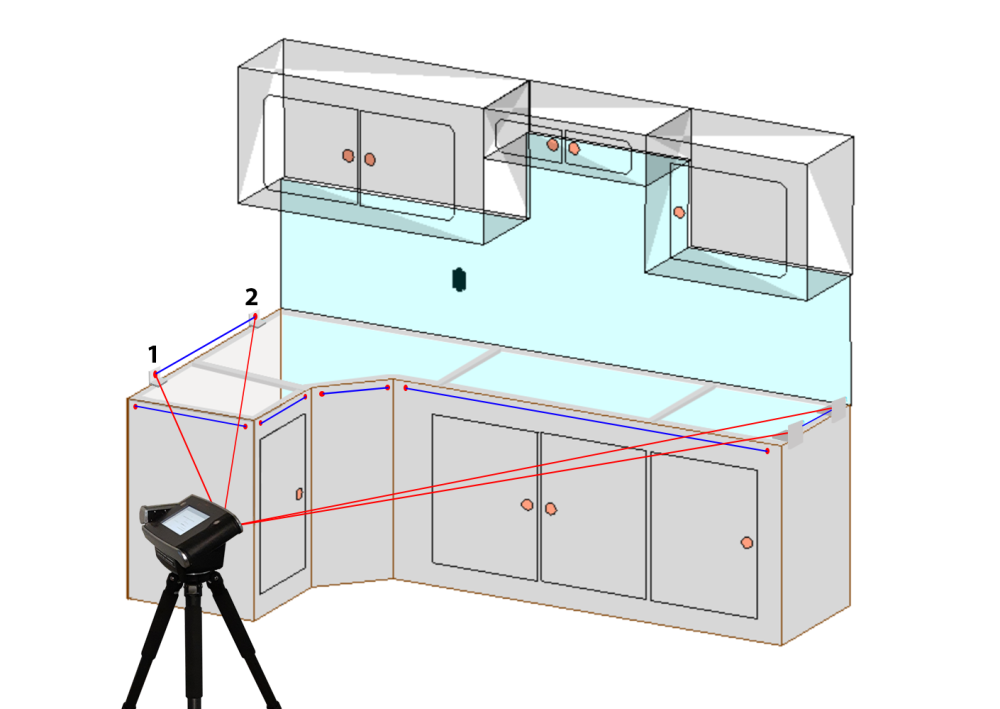

Areas that cannot be measured directly

- For those areas that cannot be measured directly from the front, you may use the included aluminum T-Targets as indicated. These targets allow the Flexijet to measure the exact edge without the need to relocate.

- The T-target is useful for measuring elements aligned with the Flexijet, providing a precise reference point in assessments. This capability ensures accurate alignment and effective measurement, making it a valuable tool in related applications.

For example, for a sink opening where one side is aligned with Flexijet and you don’t want to reposition, place the T-target marked with a line, ideally at the edge of the cabinet, and measure straight into the line on the target.

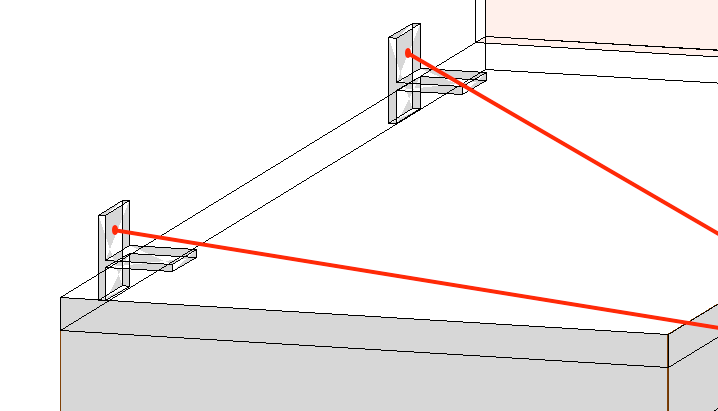

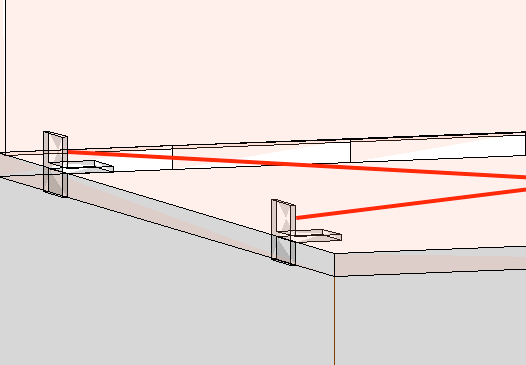

Reflective surfaces

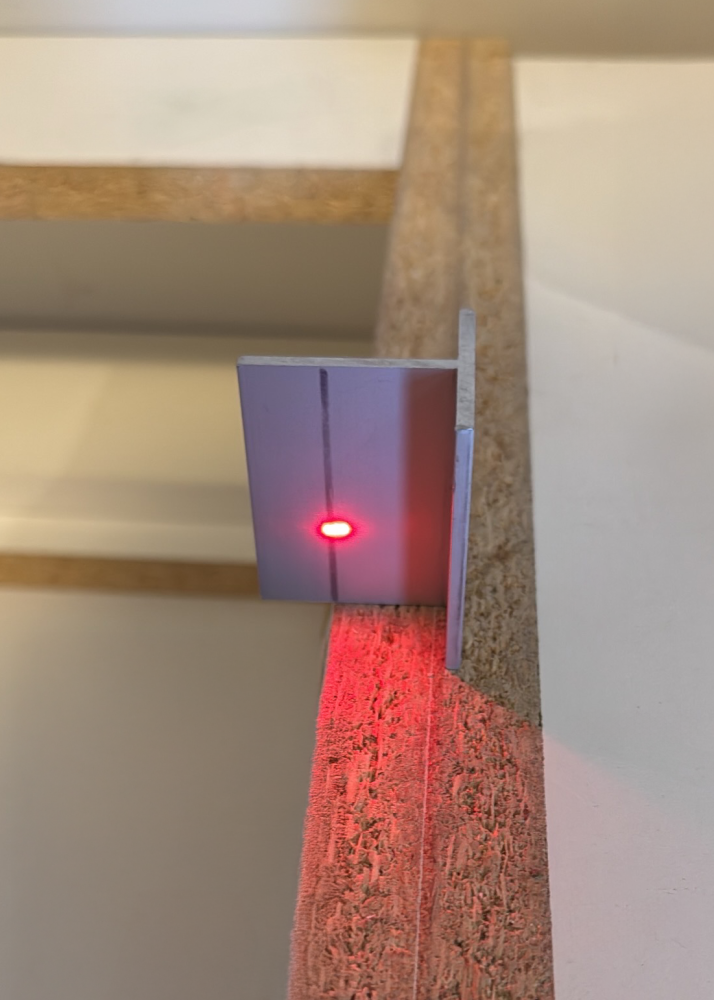

- When measuring a very reflective surface, a common tip is to use the T targets that came with your Flexijet as an offset target. If you don’t have the new laser engraved T-targets, you can draw a mark at (1 in) from the bottom or use a location sticker with the horizontal line placed 1” from the bottom. Use a remote control to aim accurately at these targets.

- You can see how to use them on reflective surfaces, such as countertops or under cabinets, where aiming the laser can be challenging without distortion. Simply aim directly at the target, avoiding any reflections, and then offset your line by 1 inch to compensate for the offset of the target.

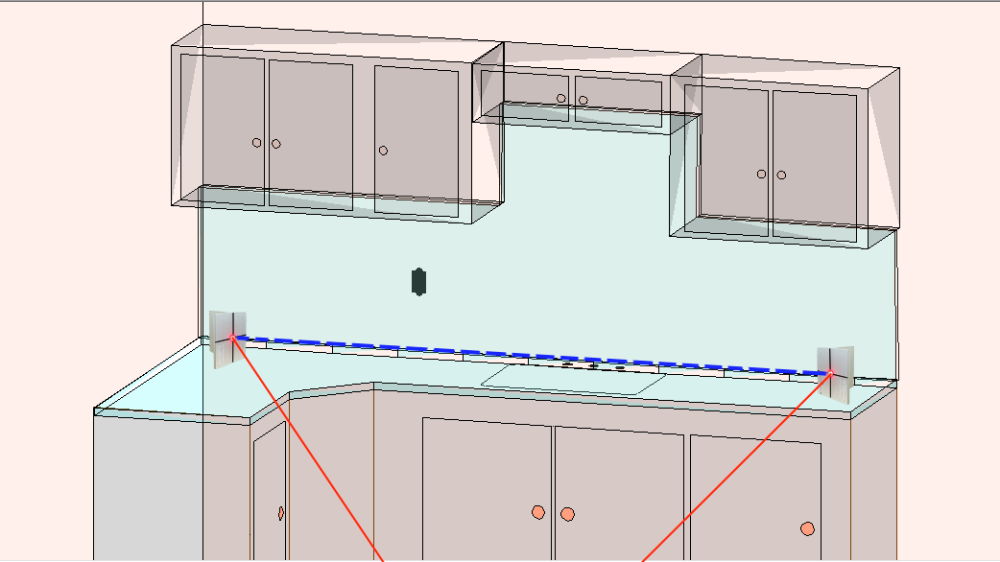

- When measuring a full-height Backsplash with very reflective surfaces on cabinets, you can use the T targets above or an Optional Handheld Laser to efficiently and accurately measure these areas. You can put a mark or a location sticker at a determined height from the bottom (Crosshair Offset).

Here you can see how to use the Optional Handheld Laser when measuring Full-height backsplash. aim the Flexijet at the target in the hand laser, and the hand laser will send the actual measurement from the countertop to the cabinet as shown with the blue line.

Clean the Flexijet Lens

Why It’s Important to Clean Your Flexijet Lens

If you’re using a Flexijet system in a dusty environment, such as construction or other job sites, keeping your lens clean is crucial for accurate measurements and the longevity of your equipment. Dust, dirt, and other debris can easily accumulate on the lens, which can negatively affect the performance of your Flexijet system.

- Accurate Measurements: A dirty lens can interfere with the laser and sensor’s ability to provide precise measurements. Even a small amount of dust can distort the laser beam, leading to incorrect data. Regularly cleaning the lens ensures that your measurements are as accurate as possible, reducing the chances of costly mistakes and rework.

- Avoid Equipment Damage: Over time, dirt and dust buildup can cause wear on the lens or other internal components of the Flexijet system. This can shorten the lifespan of your equipment and result in costly repairs or replacements. Keeping the lens clean helps protect your investment.

- Improved Efficiency: The Flexijet system works more efficiently when the lens is clear, saving you time. You won’t have to worry about recalibrating or troubleshooting issues caused by a dirty lens, allowing you to focus on your work and meet project deadlines.

In dusty industries, cleaning your Flexijet lens regularly is essential, especially if you’re working in environments with a lot of airborne particles. A quick wipe with a microfiber cloth can make a world of difference. Keep your lens clean, and your measurements will remain accurate, your equipment will last longer, and your job site will run more smoothly.

Connect to the internet at least once every two weeks

With the new License Manager in place, it’s now essential to open your software at least once every two weeks while connected to the internet. This allows the License Manager to check and confirm that everything is in order with your license. This routine check ensures that your software remains fully functional and up to date, preventing any disruptions in your work. By simply launching the software while connected to the internet, you’ll help ensure a smooth experience without the risk of license-related issues.

Post your comment on this topic.