ConveyLinx-Ai/Ai2/Ai3 24V Family |

ConveyLinx ERSC ❌ |

ConveyLinx-Ai 24V ✅ |

ConveyLinx-Ai 48V ❌ |

![]() |

![]() |

![]() |

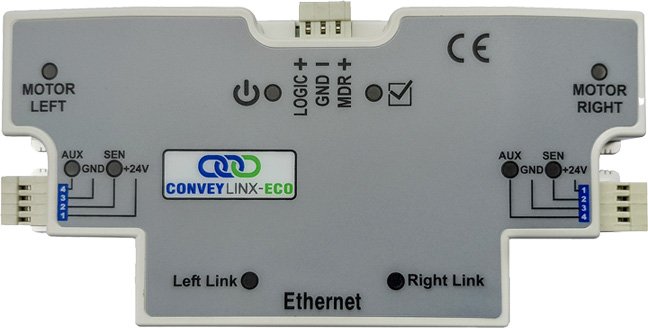

| ConveyLinx-ECO ❌ |

ZPA Mode ✅ |

PLC I/O Mode ✅ |

![]() |

![]() |

![]() |

![]()

*Note that this image shows the Left Motor Settings. The same selections apply for the Right Motor Settings

| Item |

Function |

Description |

![]() |

Motor Type |

- Dropdown of Motor Types

- Each type is related to motor performance

- List shows only types available for the controller being viewed

|

![]() |

Motor Direction |

- Selects either Clockwise or Counterclokwise

- See Motor Rotation in Appendix for more information

|

![]() |

Brake Method |

- Dropdown of Holding Brake Methods

- List shows only types available for the controller being viewed

|

![]() |

Speed |

- Value input box to enter desired speed

- Motor speed value is in percent of maximum speed of motor/gearbox being controlled

- 100 is the maximum value

|

![]() |

Use G-Force |

- When checked, motor accel / decel is based upon constant G-force

- With this setting enabled the accel time and distance is variable

|

![]() |

Acceleration |

- Value input box to enter desired acceleration value

- When Use G-Force is unchecked, the value is distance in mm

- When Use G-Force is checked, the value is in m/sec²

|

![]() |

Deceleration |

- Value input box to enter desired deceleration value

- When Use G-Force is unchecked, the value is distance in mm

- When Use G-Force is checked, the value is in m/sec²

|

![]() |

Set All |

- Click button to apply these settings to a range of modules.

- Pop-up dialogue box will provide list of other controllers to apply the settings to

- Settings will only apply to the side of the controller (Left or Right) for which you are changing settings

|

Online Motor Page of the ConveyLinx-Ai/Ai2/Ai3 24V module

![]()

| Item |

Function |

Description |

![]() |

Motor Settings |

- Includes Motor Type drop down, 7% Overspeed checkbox, Motor Direction drop down, Brake Method drop down, Speed textbox, Use G-Force checkbox, Acceleration textbox, Deceleration textbox, and the Set All button.

- The Set All button provides the ability to make a setting apply to multiple motors in one or more subnets

- This section of the image is the only portion that is available when online AND offline

|

![]() |

Force MDR Run |

- When toggled the motor will run, great for trouble shooting

|

![]() |

Motor Errors & States |

- Potential motor errors include Voltage Drop (<18V), Motor Short-Circuit, Max Torque, Overload, Motor Stalled, Motor Sensor Error, Overheat, Overvoltage, Performance Limit

- At the end of this section shows the number of Motor Errors that have been counted by the module

|

![]() |

Motor Readings |

- Includes Real Speed, Current, Motor Temperature, Module Temperature, and Operating Time

- Each represented data point will change as the reading changes when online, these values are not represented when offline

|

![]() |

Read Motor Port History |

- Shows the information for motors that have been connected to the left motor port for the left, and right motor port for the right.

- Please note that this may display testing / factory data on new modules, so seeing Japan or Europe on this log is normal.

|

![]() |

Additional Roller Diameter |

- If the Roller has a greater diameter due to the circumstance of your application (coatings, etc), this should be entered and accounted for so that the system can accurately track the roller

- Diameter must be in millimeters

|

![]() |

Special Services |

- Clear short-circuit errors on both connected motors by clicking this button

|

*More information on the motors themselves can be found in their respective manuals on our website

Post your comment on this topic.