This can plan and split tank operations based on warehouse capacities and normal scheduling constraints. It can also create CIP orders for each order while it schedules. For an example plan demonstrating how to use the TankPlanning features, see the section with a general introduction of the Batch module.

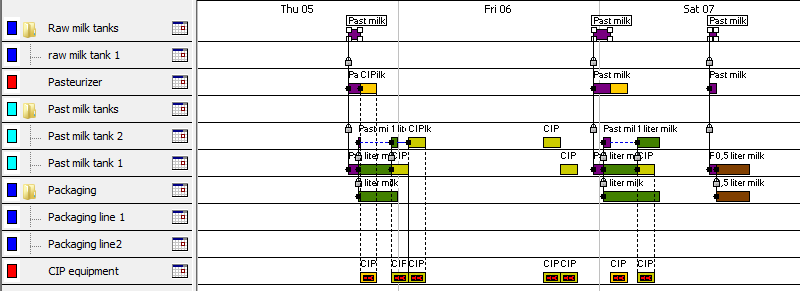

Below shows the situation before the TankPlanning macro is executed. This situation could be just after the DemandSatisfier macro has been executed where orders are created based on demands. Or it could be a manually created plan.

The TankPlanning macro can schedule the orders so no “normal” constraints are broken (normal scheduling) but furthermore it can ensure that no tank/warehouse capacities are broken. Thus it can split operations over multiple tanks while scheduling in order not to overfill a tank and not consume too much from a tank.

This shows the result after the TankPlanning macro has been executed. CIP orders have also been created by this macro during scheduling.

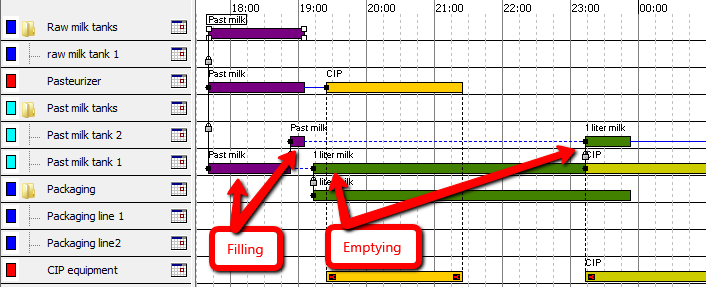

As a result the operations on “Past milk tanks” are moved and has been split to the specific resources where warehouses are assigned to. Notice that this macro works best if the routes are setup to have producing (filling) operations and corresponding consuming (emptying) operations on the same resource! On the Past milk tanks resources the purple operations are fill-up operations and the green and brown are emptying operations.

See example of Filling and Emptying below:

- A ROB-EX example plan and macro configuration is located in the data folder: \data\batchDemo ( ). The general introduction of the Batch module explains how to setup and use this file. This file can be opened in a ROB-EX client using the “File->Open” menu option, while not being logged into a ROB-EX Multiuser Server, and contains example setup of master data etc.

- See the CreateCIP section in order to setup the CIP (Clean In Place) functionality.

- “Tank split” must be enabled on the operations to split, i.e. if this flag is not set the TankPlanning macro will not try to split operations according to warehouse sizes:

- A warehouse must be assigned to each tank resource – where tank operations should be planned and split.

- A max. level (capacity) must be defined for each warehouse:

- The Batch module is needed.

- See the general description of the Batch module for more information

Parameter descriptions

(* = configuration required)

cipOrderColor

Specify the color of the CIP orders to be generated. Only relevant if “runCIP” is enabled.

Possible colors (must be typed exactly as below):

white

lightGray

gray

darkGray

black

red

pink

orange

yellow

green

magenta

cyan

blueDefault “yellow”

clean

If true the selected orders are reset back to the resource groups, operations are joined and CIP is removed.

Default false

collectDependenciesInRoute

If true the orders linked to the currently selected orders will also be planned.

Default false

collectDependenciesOnResource

If true the orders on the same resource, affected by the planning will also be planned.

Default false

forwardFromNow

If true the orders are planned forward from now. Otherwise they are planned forward from their current location.

Default false

maximumSolutions

When running tank planning, several different resource combinations are examined, this parameter tells the algorithm to keep trying until the specified number of valid solutions are found (only works with version=2)

Default 10.

moveOperationToGroupBeforeScheduling

Indicates if all operations are be moved to group level before scheduling is started. This is necessary if you are working with a resource matrix.

respectBOMConstraints

If true the planning will also check for available material in stock.

Default false

runCIP

If true CIP orders will also be created, based on the rules setup per resource. See the CIP manual.

Default false

Version

Default 1

Post your comment on this topic.