This macro will analyze the selected orders and create CIP orders, if necessary, according to the CIP rules. For an example plan demonstrating how to use the CIP rules, see the general introduction of the Batch module.

The picture below shows four orders before the macro has been executed. The resources “Pasteurizer” and the “Past milk tanks” are configured to be “CIP’ed” (see preconditions below).

The picture below shows the result after the macro has been executed. Two CIP orders have been created (the yellow operations).

Two different rules are used. On the Past milk tanks a “Tank” rule is used and on the “Pasteurizer” an “Equipment” rule is used . Those rules are setup per resource, as explained in the preconditions chapter below.

On the above screenshot a CIP is created after the first pasteurizer operation (purple) but not after the second operation. This is because the cleaning interval is set to 20 hours and thus a cleaning is not needed after the second pasteurizer operation.

On the “Past milk tank 2” a CIP is created after the emptying operation (the green one). in that way it is ensured that a tank is not scheduled for a cleaning while it is not empty.

Example 2

On the below example the second milk order has been delayed to the next day – which causes some more CIP orders to be created, since more than 20 hours has passed since the previous CIP.

On the second pasteurizer operation the cleaning interval has been exceeded so a CIP is created just before. Also on the second filling operation (the purple one on “Past milk tank 2”) the interval has been exceeded and thus a CIP is created just before the filling ´.

Also notice how CIP orders are planned taking the limited capacity of the available CIP equipment into consideration. I.e. in the above example there is only a single piece of CIP equipment available.

- Operations to analyze cannot be assigned to a resource group. They must be assigned to a specific named resource in order to be considered valid for the CIP planning.

- A route and a rule must be specified on each resource (or just on the resource group) where a CIP should be created.

This is done in “Edit -> Resource” on the “Scheduling” tab:

The “Route” combo box will show template routes where the “CIP” flag is enabled (possibly manually add the “CIP” column to the Edit->Route table if not shown for your configuration):

- If the cleaning interval is not specified a default value of 20 hours will be used.

- CIP orders are created called “CIP”, based on the specified template routes.

- The analyzed orders are scheduled forward from current position after the CIP creation. This is done to avoid a possible overlap with the new CIP orders.

- For developers: Additional CIP rules can be added through the API. Implement the interface “CIPRule” and add it by calling “addCIPRule(…)” on the BaseModelAPI class.

- The Batch module is needed.

- See the general description of the Batch module for more information

Parameter descriptions

(* = configuration required)

cipOrderColor

Specify the color of the CIP orders to be generated.

Possible colors (must be typed exactly as below):

white

lightGray

gray

darkGray

black

red

pink

orange

yellow

green

magenta

cyan

blueDefault “yellow”

clean

If true the CIP orders are removed for the selected orders. It is not needed to select the CIP orders.

Default false

operationSelectionStrategy

Here it can be specified which operations should be passed on to the CIP rule – and how.

- entireRoute

- The other operations in the route of the selected operation(s) will also be analyzed for CIP. (the CIP rule is called for each single operation) Default.

- none

- No operations should be selected. Used if a resource (or group) is specified on the macro in the “resourceName” field.

- selectedOperations

- The selected operations only will be analyzed – one by one (the CIP rule is called for each single operation).

- selectedOprList

- The selected operations only will be analyzed – the whole list is passed to the CIP rule – and it will by it self decide which operations to create CIP for. At present time only the following rules support this strategy:

“CIP before earliest and after latest of the selected operations”

Default is entireRoute

resourceName

Specify a resource (or group) name in order to have CIP orders created with certain cleaning interval on that resource – independently of existing orders (no operations should be selected).

At present time only relevant for the following rules:

- “CIP with fixed cleaning interval”

“none” must be specified in operationSelectionStrategy.

Hints:

Specify this parameter in the “Specifications” field on “Edit -> Resource” dialog in order to have multiple CIP orders created with one click. A maximum count up to 50 is allowed.

CIP_with_fixed_cleaning_interval_CIP-count-per-click=10;

If a resource group name is specified and the CIP rule and cleaning interval is set on that group all group members with the same CIP rule set will have CIP orders created on them.

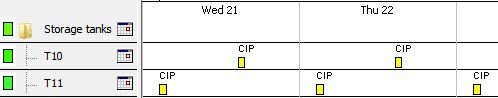

In below example a CIP order is created each 12 hours on T10 and T11.

How to set this up:

Macro:

Resource group (Storage tanks):

T10 and T11:

Post your comment on this topic.