“ALL OTHERS” MATERIAL DIVERSION CALCULATION BY COMBINED WEIGHT

Project teams may follow the calculation steps below to help calculate compliance with the “All Others” material diversion rate listed in Table 16-1. A weighted average is used to determine the combined diversion rate for these materials.

For each material considered part of “all other” materials:

Step 1 – Calculate the individual material’s total weight.

Step 2 – Establish the material-specific Diversion Rate, typically from the recycling facility.

Step 3 – Determine the Diversion Factor for each material.

Diversion Factor = Total Weight of Material/Total Diverted Weight of “all other” materials.

Step 4 – Determine the weighted diversion rate (%).

Weighted Diversion Rate (%) = Diverted Rate x Diversion Factor

Repeat Steps 1 through 4 for all materials.

After “all other” materials Weighted Diversion Rates are established:

Step 5 – Add all the Weighted Diversion Rates together to determine the combined weighted diversion rate.

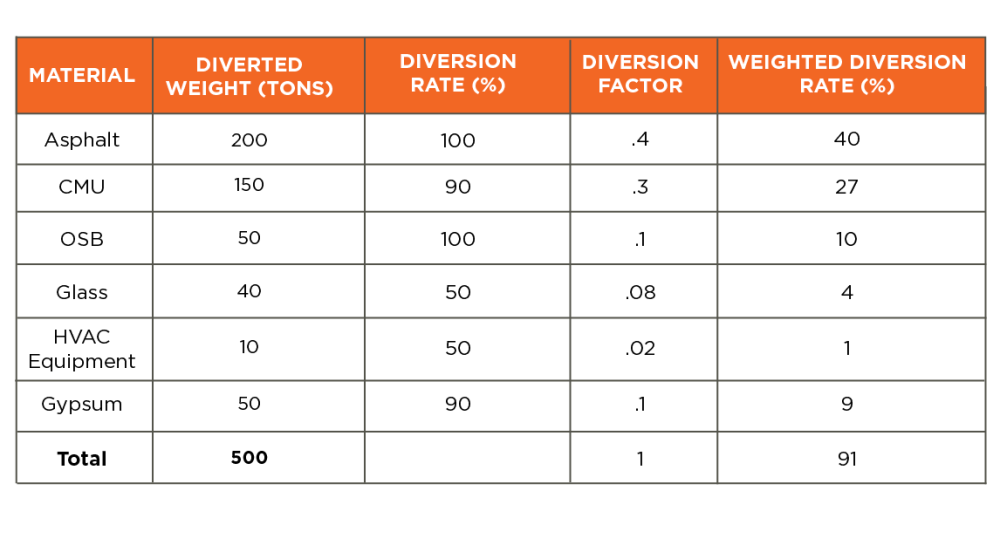

EXAMPLE CALCULATION – MATERIAL DIVERSION RATE BY COMBINED WEIGHT

Assume the following diversion weights and diversion rates. Calculate the diversion factor and the weighted diversion rate for each material and for all of the material together:

Step 1 – Calculate the individual material’s total diverted weight.

- Diverted Weight of Asphalt = 200 tons

Step 2 – Establish the material-specific Diversion Rate, typically from the recycling facility.

- Diversion Rate of Asphalt = 100%

Step 3 – Determine the Diversion Factor for each material.

Diversion Factor = Weight of Material/Total Diverted Weight of all “other materials.”

- Diversion Factor of Asphalt = 200 lbs/500 lbs = 0.4

Step 4 – Determine the weighted diversion rate (%).

Weighted Diversion Rate (%) = Diverted Rate x Diversion Factor

- Weighted Diversion Rate of Asphalt = 100% x 0.4 = 40%

Step 5 – After repeating Steps 1-4 for all materials, add all individual Weighted Diversion Rates in the final column.

- For all materials in the table above: Combined Weighted Average = 91%.

“ALL OTHERS” MATERIAL DIVERSION CALCULATION BY LINE ITEM AVERAGE

For each material considered part of “all other” materials:

Step 1 – Calculate the individual material’s total weight.

Step 2 – Establish the material-specific diverted weight, typically from the recycling facility.

Step 3 – Repeat Steps 1 through 2 for all materials.

Step 4 – Add up the totals of all individual weights.

Step 5 – Add up the totals of all material-specific diverted weights.

Step 6 – Divide the total diverted weight of all materials by the total weight of all materials to get the average diversion rate (%).

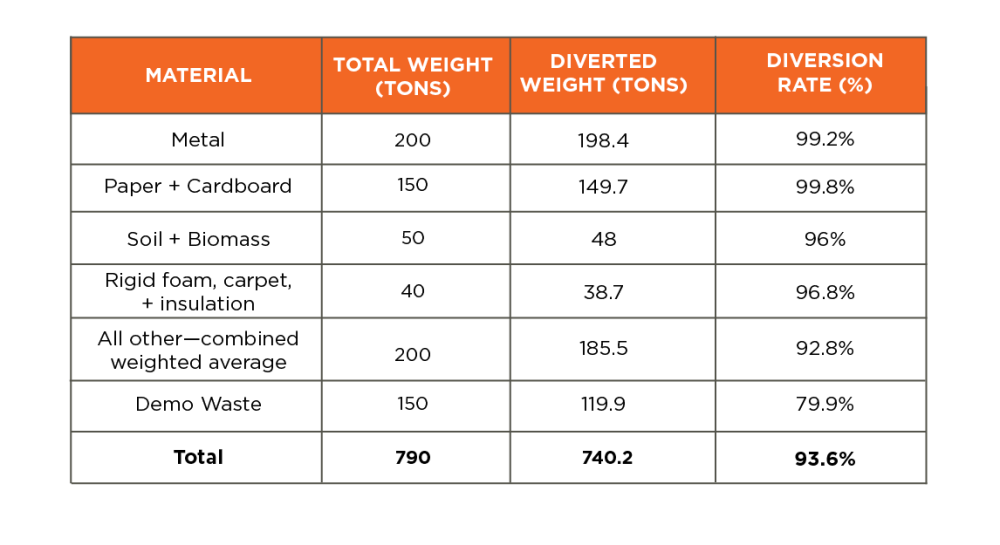

EXAMPLE CALCULATION : MATERIAL DIVERSION RATE BY LINE ITEM AVERAGE

Assume the following material weights and diverted weights. Calculate the diversion rate for each material and for all of the materials together.:

Step 1 – Calculate the individual materials total weight.

- Total weight of Metal = 200 tons

Step 2 – Establish the material-specific diverted weight, typically from the recycling facility.

- Total diverted weight of Metal = 198.4 tons

Step 3 – Repeat Steps 1 through 2 for all materials.

Step 4 – Add up the totals of all individual material weights.

- Total material weight = 790 tons

Step 5 – Add up the totals of all material-specific diverted weights.

- Total diverted material weight = 740.2 tons

Step 6 – Divide the total diverted weight of all materials by the total weight of all materials to get the average diversion rate (%).

- Average diversion rate = 740.2/790 = 93.6%