The decision to “Clear Connections” is based upon the application. When a string of modules are Auto-Configured, each successive module in the string establishes a logical upstream / downstream connection with its neighbor module’s. These connections provide the basis for the logical flow of inter-module status data for ZPA functionality. However, if a single module node within a string of ZPA configured nodes needs to be utilized in PLC I/O mode, these logical connections can remain in place and be used to PLC programmer’s advantage.

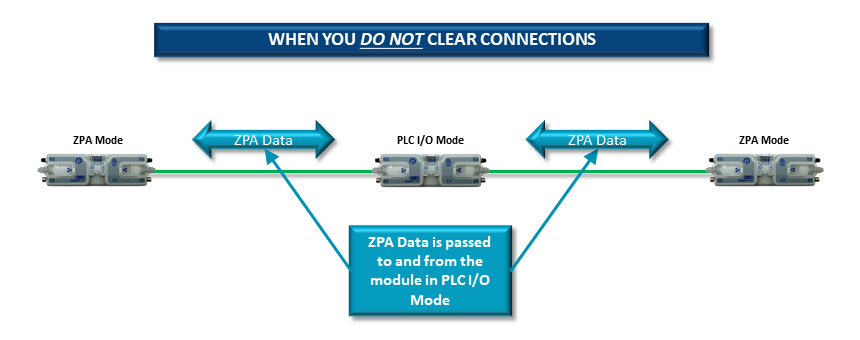

When You DO NOT Clear Connections

By NOT clearing the connections, the module in PLC I/O will maintain its inter-module data exchange. This could be advantageous for applications where you want to control a specialized conveyor section such as a right angle transfer or merge conveyor with an ERSC in PLC I/O mode. For example, if the PLC I/O mode module is being either fed or feeds conveyors controlled by modules in standard ZPA mode, these modules will populate PLC I/O configured module’s registers with their respective status data. Likewise, the PLC can manipulate the PLC I/O configured module’s zone status registers and these registers will automatically be written to the adjacent modules by virtue of these already established connections without requiring the PLC to explicitly perform the messaging.

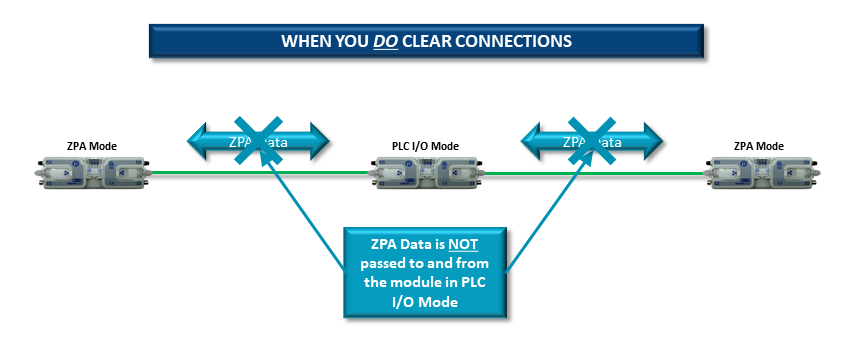

When You DO Clear Connections

If you choose the option to “Clear Connections”, this automatic data transfer of status is inhibited. This means that for a module in PLC I/O mode whose connections have been cleared; its status registers are not automatically written to its adjacent neighbors. Clearing the connections could be advantageous when utilizing several modules in a row configured as PLC I/O where having this additional inter-module communication is not required and would only add to unnecessary communication bandwidth usage.