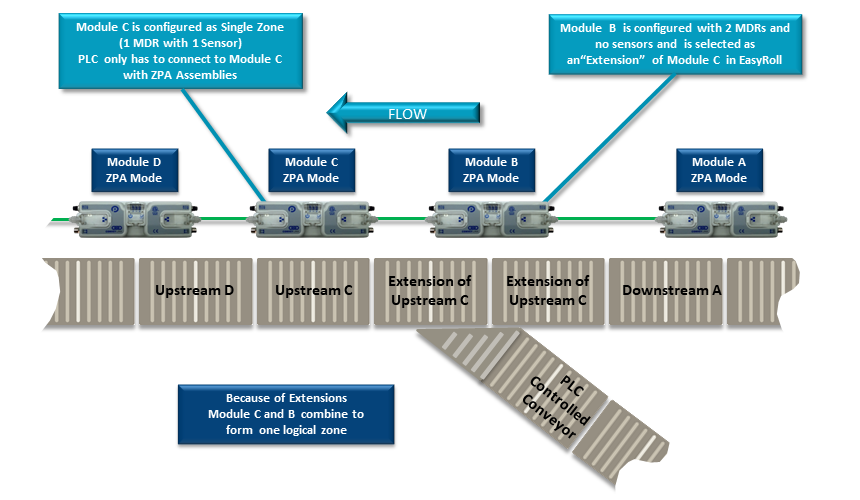

This example shows how to perform a simple merge with only a single module connection to the PLC. In this example the PLC only needs to connect to Module C and from this connection, the PLC can monitor conditions on Module A as well as “wake-up” Module C / Module B zone to accept a carton from the merging curve section.

- With no PLC intervention, as long as cartons arrive into Module A they will be conveyed to Module C/B and onto Module D in normal ZPA fashion.

- To verify that Module C (and by extension Module B) is ready to accept a carton from the merge curve; the PLC needs to know that Module C’s zone is clear and stopped by examining Local Status Upstream Zone Forward Direction register (Low Byte). When the low byte of this register equals 1, the zone is clear and stopped.

- When the PLC needs to convey a carton from the merging curve, the PLC needs to set bit 8 in Accumulation Control for Local Upstream Zone register to accumulate the adjacent upstream zone, in this example setting bit 8 will cause Module A downstream zone to accumulate any carton that arrives.

- When the PLC is ready to release a carton from the PLC Controlled Conveyor spur, the PLC sets bit 12 in the Accumulation Control for Local Upstream Zone register to wake up the Module C zone (along with Module B’s zones because Module B is an extension of Module C).

- When the PLC sees the low byte of the Local Status Upstream Zone Forward Direction register change to a value of 4 or 5, the PLC knows that the carton made it to Module C’s zone sensor and must then reset bit 12 in the Accumulation Control for Local Upstream Zone register. Either of these values will indicate a successful arrival at Module C

- Upon reset of bit 12 of the Accumulation Control for Local Upstream Zone register, the PLC can reset bit 8 of the same register to indicate to Module A that it is OK to continue normal ZPA function