PLC Developers Guide / PLC I/O Mode Control / PLC Outputs for PLC I/O Mode /

Servo Control |

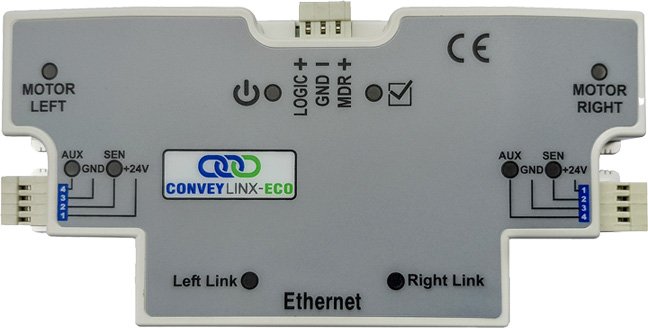

ConveyLinx ERSC ✅ | ConveyLinx-Ai 24V ✅ | ConveyLinx-Ai 48V ✅ |

|

|

|

|

| ConveyLinx-ECO ✅ | ZPA Mode ❌ | PLC I/O Mode ✅ | |

|

|

|

| Register Name | Internal Address | Assembled PLC Address | Description | ||

| Set Servo Position Value Left Motor |

4:0008 | M: 4:1823 E: O.Data [23] P: Byte 46 (Hi) P: Byte 47 (Lo) |

Signed Integer Value | ||

| Value of the position to move to on the next Left Motor Servo Run Command | |||||

| MDR = | Value is in mm | ||||

| PGD = | Value is in Motor Pulses | ||||

| Range = | -32767 to +32767 | ||||

| Set Servo Command Word Left Motor |

4:0009 | M: 4:1824 E: O.Data [24] P: Byte 48 (Hi) P: Byte 49 (Lo) |

Bitwise Value | ||

| Bit 00 = | Set Bit to Reset Left Motor Servo Position Value to 0 | ||||

| Bit 01 = | Set to Initiate Run Left Motor to position set in the Left Motor Servo Position Value Register | ||||

| All other Bits reserved | |||||

| Set Servo Position Value Right Motor |

4:0013 | M: 4:1825 E: O.Data [25] P: Byte 50 (Hi) P: Byte 51 (Lo) |

Signed Integer Value | ||

| Value of the position to move to on the next Right Motor Servo Run Command | |||||

| MDR = | Value is in mm | ||||

| PGD = | Value is in Motor Pulses | ||||

| Range = | -32767 to +32767 | ||||

| Set Servo Command Word Right Motor |

4:0014 | M: 4:1826 E: O.Data [26] P: Byte 52 (Hi) P: Byte 53 (Lo) |

Bitwise Value | ||

| Bit 00 = | Set Bit to Reset Right Motor Servo Position Value to 0 | ||||

| Bit 01 = | Set to Initiate Run Right Motor to position set in the Right Motor Servo Position Value Register | ||||

| All other Bits reserved | |||||

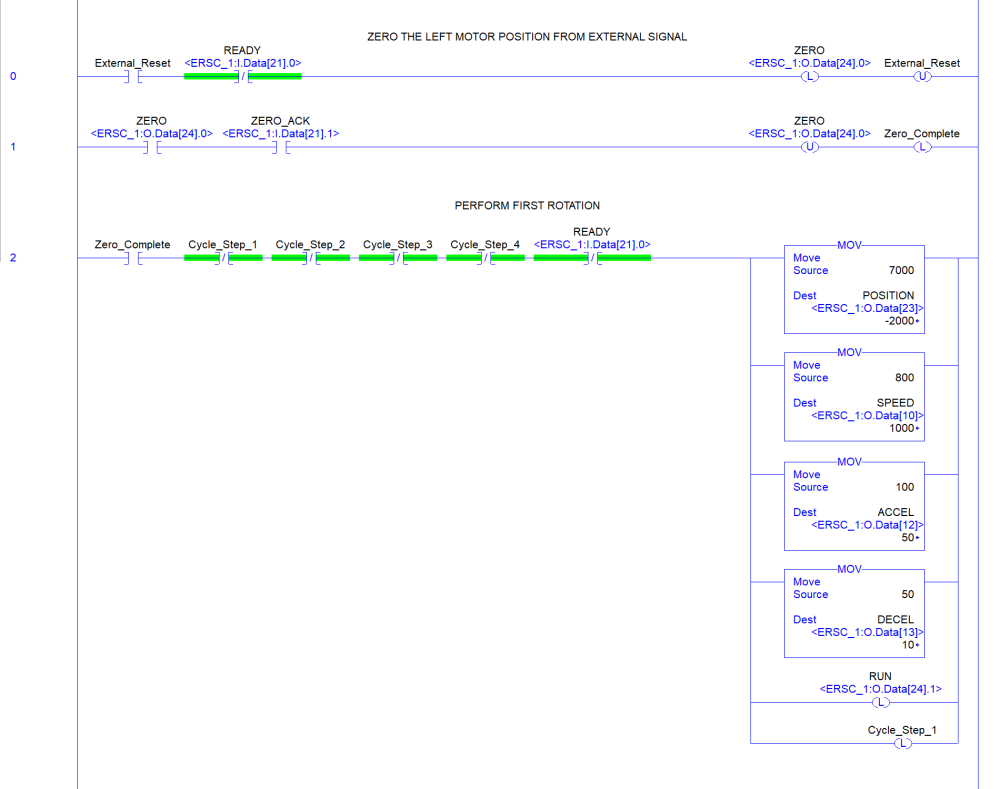

- Servo Control Example

For our example, we want to perform the following cycle using PLC control of the Left MDR on an ConveyLinx Module:

- Establish a zero or home position by external input to the module form a PLC (sensor or operator button)

- Rotate in the CCW direction for 7000 mm at a speed of 0.8 m/s with acceleration ramp of 100 mm and a deceleration ramp of 50 mm

- Rotate the CW direction for 9000 mm at a speed of 1.0 m/s with acceleration ramp of 50 mm and a deceleration ramp of 10 mm.

- Rotate CCW back to the zero or home position at a speed of 0.8 m/s with acceleration ramp of 50 mm and a deceleration ramp of 10 mm.

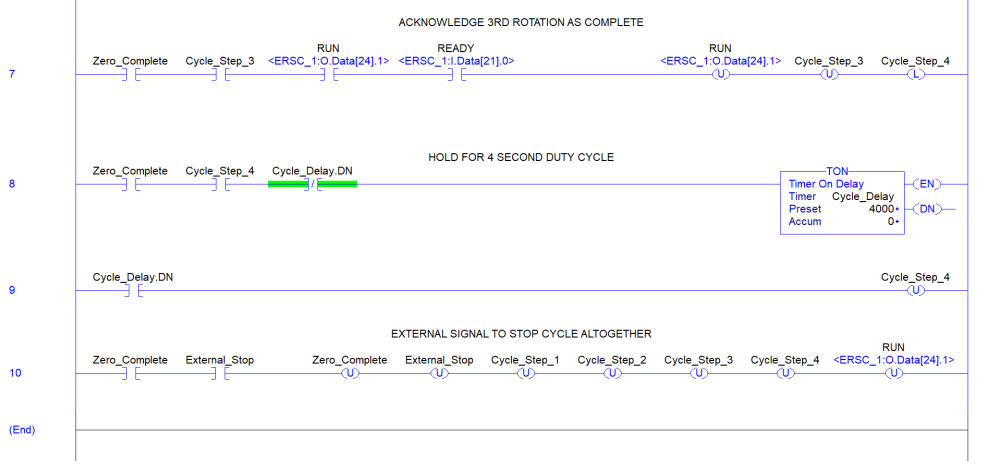

- Wait for a cycle dwell time of 4 seconds and then repeat the rotation cycles

Define PLC Tags

Tag Name Data Type Assembly Register (/bit) ZERO Boolean Left Servo Command Word – bit 0 ZERO_ACK Boolean Left Motor Servo Status – bit 1 RUN Boolean Left Servo Command Word – bit 1 READY Boolean Left Motor Servo Status – bit 0 POSITION Integer Left Servo Command Pulses SPEED Integer Left Motor Speed Reference ACCEL Integer Left Motor Acceleration Ramp DECEL Integer Left Motor Deceleration Ramp Sequence of Operation

Step #1: Upon external signal from sensor or button, set ZERO bit to establish zero or “home” position. When PLC sees that the ZERO_ACK bit is set, then the PLC resets the ZERO bit.

Step #2: To make the first rotation, we need write the speed, ramp values, and distance to rotate to the appropriate registers:

- Write 800 to SPEED

- Write 100 to ACCEL

- Write 50 to DECEL

- Write 7000 to POSITION

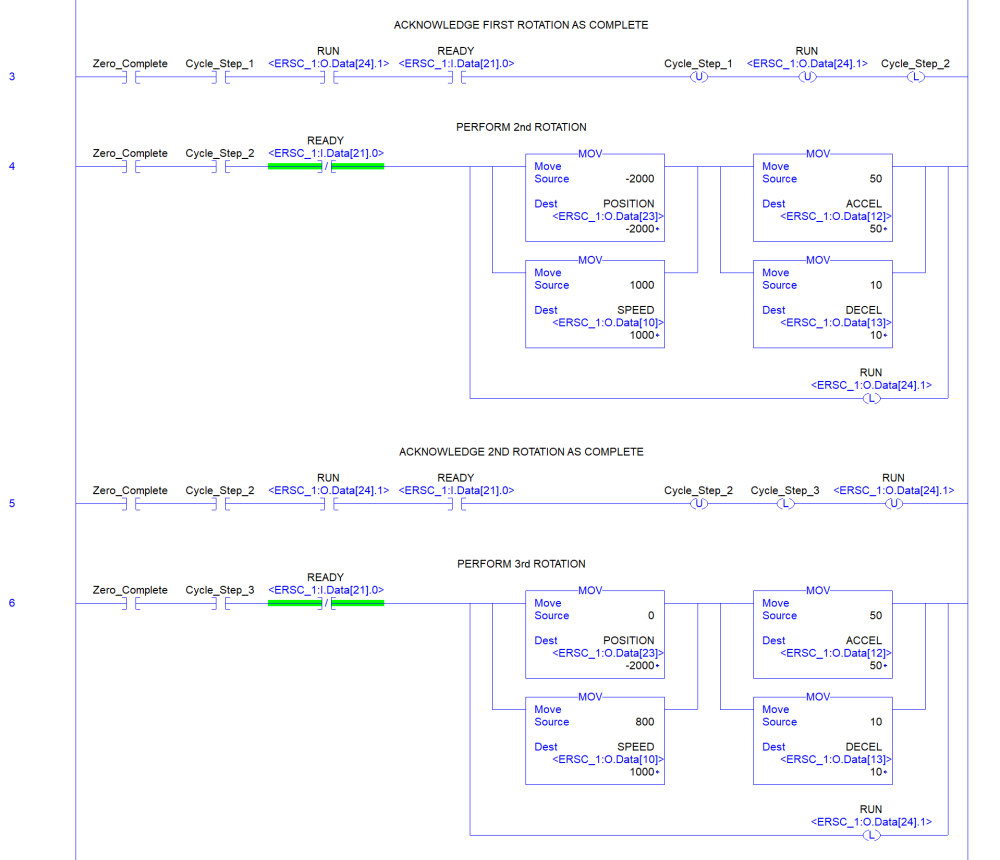

Step #3: If READY is reset, then the PLC can set the RUN bit to begin the rotation. When the rotation is complete, the module sets the READY bit. This will be the signal to the PLC to reset the RUN bit. Once the module sees that the RUN bit has been reset, it will reset the READY bit.

Step #4: For the second rotation, we need to write the speed and ramp values to the appropriate registers:

- Write 1000 to SPEED

- Write 50 to ACCEL

- Write 10 to DECEL

Because we want to rotate in the opposite direction, we need to determine the new location based upon the zero or “home” position. In this case, we know we went 7000 mm “forward” and we want to move 9000 mm “backward”. The position we want to end up is 7000-9000 = -2000.

- Write -2000 to POSITION

Step #5: Repeat Step #4

Step #6: For the 3rd rotation, we keep the ramp values from the 2nd rotation, but we need to set the speed and the position to rotate. In this case we want to go to the zero or “home position.

- Write 800 to SPEED

- Write 0 to POSITION

Step #7: Repeat Step #4

PLC Ladder Diagram