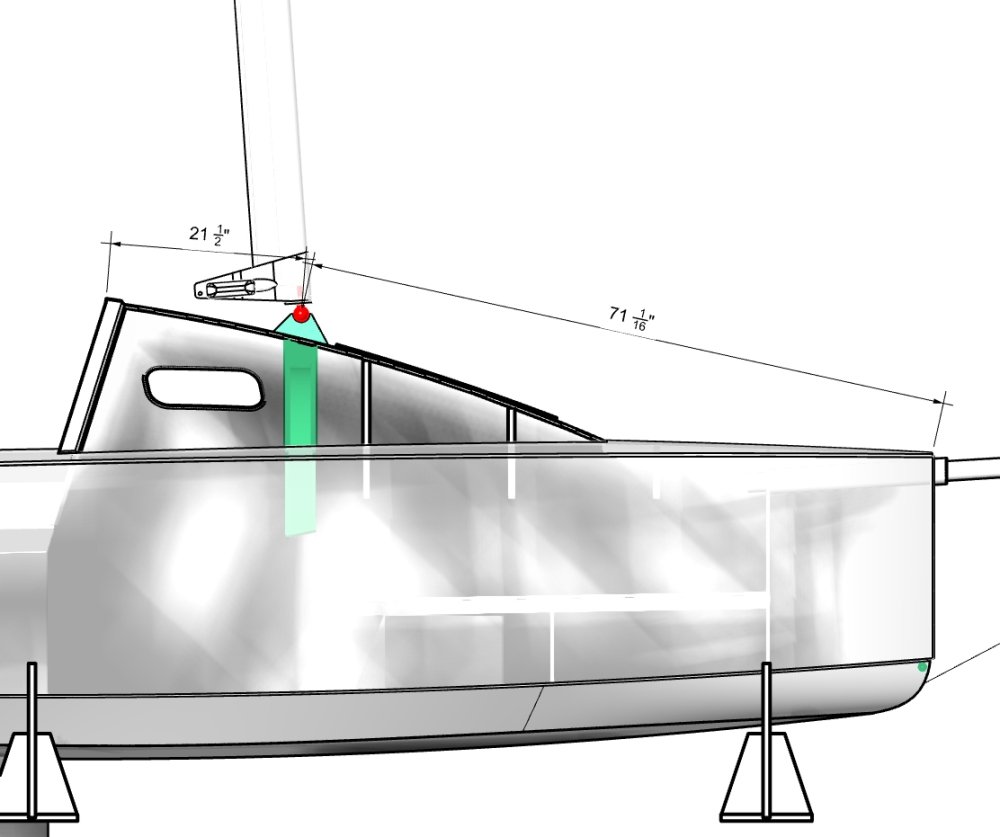

This is the best stage to install a mast base block. The boat is setup to use a stock Hobie 16 mast and as such the easiest option is to buy a replacement mast base socket. These sockets are set up to mount on the Hobie front beam and as such they have a cupped base. You will need to shape a block of wood to fit the cabin top and also the mast socket. The other purpose of the mast base block is to distribute the compression loads from the mast to the internal mast beam. As such, it is important to taper out the base of the block so that it spreads this load to a large area of the cabin top. Once you have shaped your block, use thickened epoxy to glue it onto the cabin top as shown. Then sweep a generous fillet around the block and then wrap the block with at least 3 layers of 8.8 oz fiberglass. Taper out the laminate layers on the cabin top stopping no less than 4 inches from the block.

Post your comment on this topic.

Brandon wrote: Aug 27, 2023

No, you do not have to hog out the foam in that area. One of the functions of the mast base block is to spread the compression load into a large enough area that the foam can easily handle it. It is important to do a nice job laminating at least 3 layers of 8.8 oz cloth over the block extending a few inches past.

Kurt wrote: Aug 27, 2023

Do you hog out the foam from the cabin top so that wood mast step does not compress the cabin top foam that it is mounted upon? If so, should thickened epoxy be used in the hogged out recession?