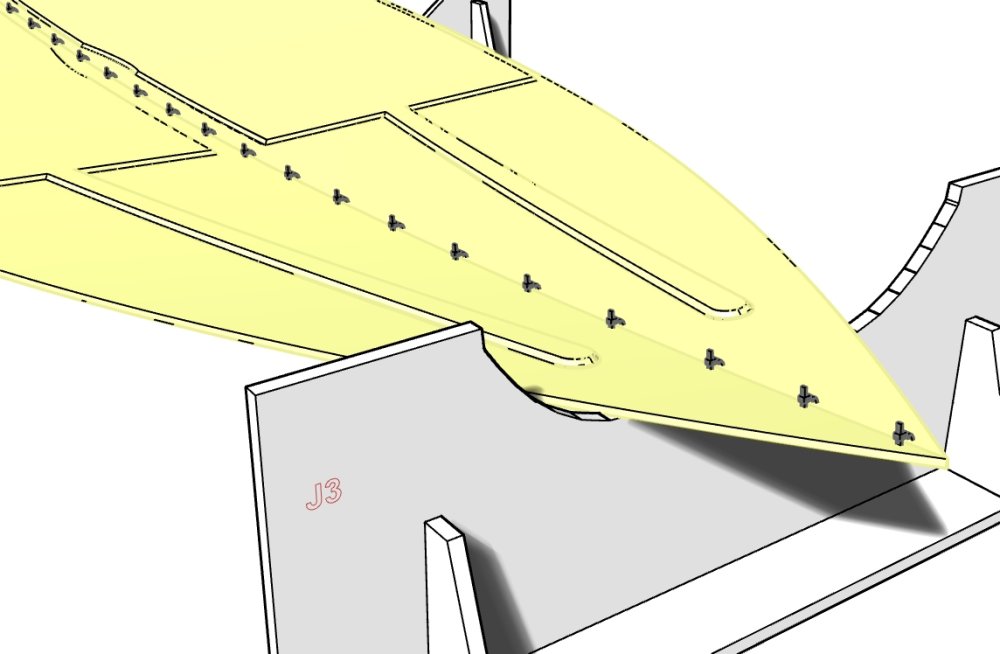

Making a Boat- Put some masking tape along the top edges of the building jig to help prevent the boat from sticking to them. The first panels H1-P and H1-S need to lay ontop of the building jig with their labels facing up. There are marks which will show where the panels sit on the Building Jig. Try to align these as to the marks as closely as you can.

Zip Ties- Drill small 1/8” holes in the panels about 1/2” in from the edge along the seam you are joining. I like to start at one end of the joint, drill 4-6 matching sets of holes, and then loosely zip tie them together as I go. Hole spacing should be roughly 6” but do not hesitate to drill more holes where needed. The goal is to pull the panels together just enough that they stay in place. You do not need to over tighten these zip ties. Double check that the panels are lined up nicely and then brush on some epoxy over the exposed seam. Do not brush over the zip ties, but be sure there is plenty of epoxy saturation down into the crack between the panels. Let the epoxy fully cure and then remove the zip ties. Double check that the seam is nice and straight and then apply thickened epoxy with a squeegee over the crack and the zip tie holes. The goal is to have a nice smooth transition between the panels that will be easy to apply a layer of glass.

Sand the centerline smooth and devoid of shiny areas that might hinder adhesion. Apply 2” wide fiberglass tape along the centerline seam (6oz or a cut strip of 8.8oz). Fully saturate with epoxy until translucent with no voids or bubbles. Sweep a 1/2“r fillet around the perimeter of the foam doubler panels to make a nice transition for laying glass. Let the epoxy fully cure and then sand .

Laminate two layers of 8.8oz fiberglass over the bottom doublers. The fiberglass should extend about 1” past the foam doubler edges. Apply one or two fill coats of epoxy to this area as it will be the floor (cabin sole) of the finished boat.

Post your comment on this topic.

Brandon wrote: Nov 12, 2022

Wire rips through the foam too easily and thus zip ties are the best. 1/8" or the next size up are good. Start out with very little tension and add just enough to pull the panel edge to the desired shape--- Do not over tighten. The edges do not need clamping pressure and a bit of daylight seen is ok. The most important thing is that the edges meet forming a nice fair line... the epoxy and glass will do the rest.

Matt Ratliff wrote: Nov 12, 2022

Can we use wire? Any wire bailing or copper wire? And what size zip ties, as small as we can get or thick ones.