How to avoid building a Crooked Boat

Before you mix up epoxy and lock the bottom panels into their shape, it is very important to align your building jig. The building jig needs to be level, which will insure that the bottom panels are taking on the proper rocker. But more importantly, the building jig alignment will control the twist. Without proper alignment in this step, it is easy to build a boat that is twisted and in the worst case may want to always turn in one direction. Twist can also cause issues when fitting the next panels and misalignment tends to multiply as you assemble more pieces of the boat. If left unchecked, you may find that the last pieces of the boat do not want to fit together at all. By paying close attention to the alignment of these first panels, you will be making your life a lot easier on the next stages of building the boat.

Check that they are Parallel

Accurately measure with a tape measure that the building jig edges are equal distant from each other. During this process you should be keeping an eye on the panels and insuring that the marks on the foam core line up with the building jig.

Using a Laser Level to Level the Building Jigs

Look closely on the building jigs for the scribe line that denote the “Water Line” of the building jigs. In boat building jargon, a “Water Line” does not have to be the actual water line that the boat will float on but is a reference plane that the boat is built from. Some boats and jigs will have multiple “Water Lines” up the entire structure that are used as reference planes when building the boat. For the Skate 15, the scribe lines on the building jig should be setup to form our reference “Water Line”. If you happen to have a laser level, you can use it at this stage to make sure that all the scribe lines are perfectly lined up to the laser plane that your laser projects. Setup the laser so that it projects onto all three build jigs at the same time so that you do not have to re position the laser as you align the build jig. Use wedges under the build jigs to shim them into position. Once you are happy that everything is perfectly level then it is a good idea to hot glue the jigs (and wedges) down to your floor to make sure they do not get bumped later on. Also, it is prudent to recheck the alignment of your build jig each time you are epoxying another panel onto the boat to insure the boat is assembled level and without twist.

Alternative -Using Fishing Line to Level the Jigs

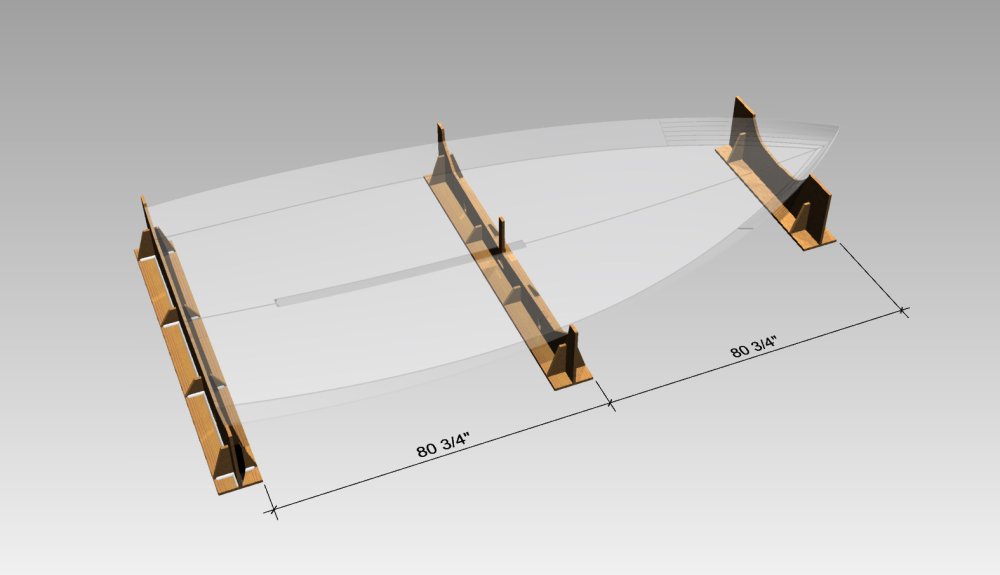

Use mono filament fishing line to string between the building jigs as shown in the picture as red lines. You want the line to travel unencumbered along the building jig so that it does not touch the plywood of the middle building jig. Use tape, or screws to attach the ends of the lines well away from where it wraps around the plywood at the waterline scribe. The lines that travel parallel along the sides are to insure the build jig is level and square. The lines that cross in the middle are to insure that there is no twist. These lines should just barely touch. If one of these is not touching or is pulling on the other string then shim a corner of the stern jig until they are just lightly touching where they cross. Again, this is a very important step so take time to get this alignment right. When you are satisfied that they are aligned perfectly, hot glue the building jigs to the shop floor if possible. Also, recheck these before you epoxy each plank to insure the boat is assembled level and without twist.

Post your comment on this topic.