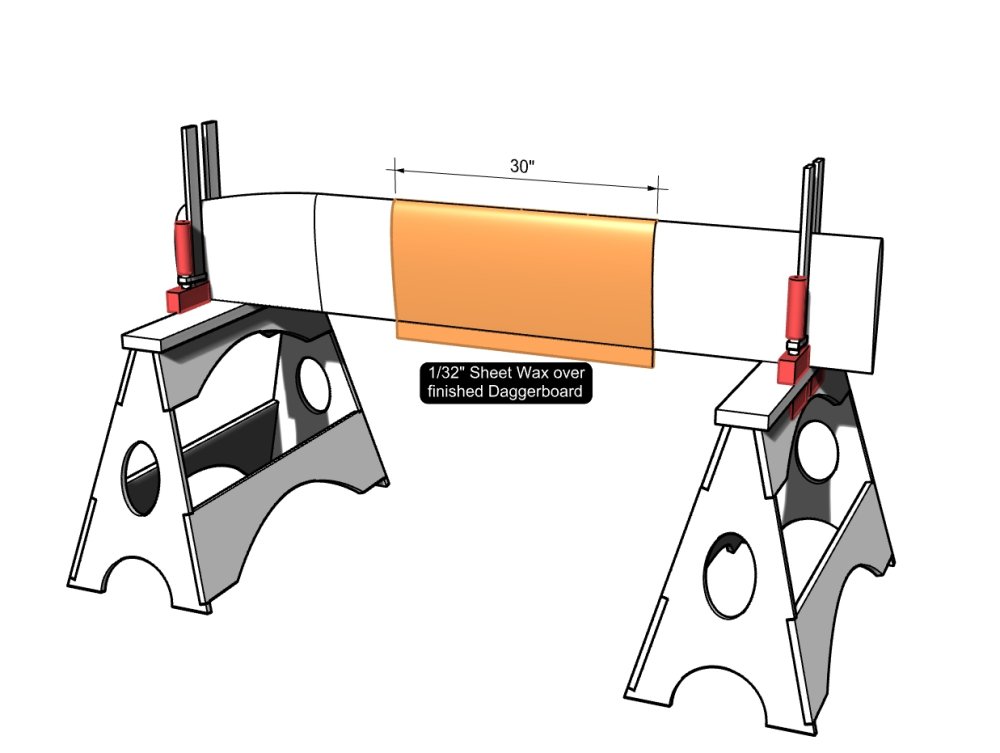

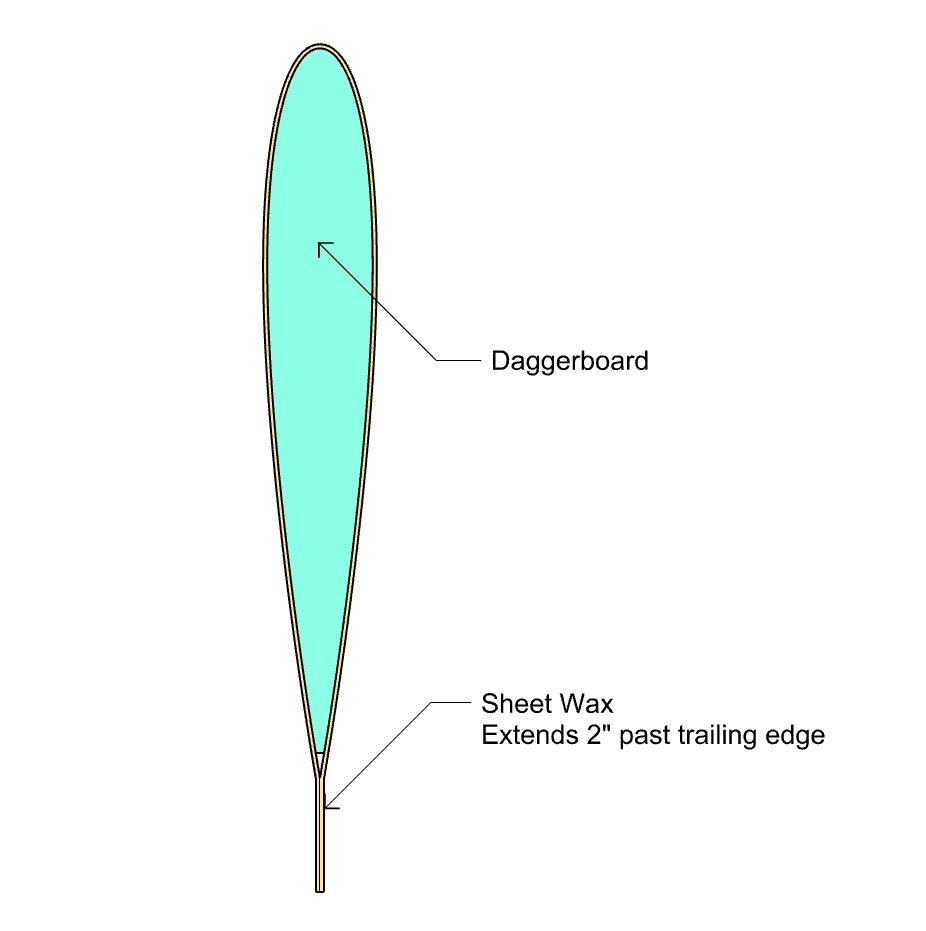

Making a mold surface. Once your daggerboard is fully finished it is time to make a daggerboard trunk. Set your daggerboard up on saw horses so that it stands up and is stable to work on. Then take 1/32” thick wax sheet and apply it over a 30” long straight section of the Daggerboard with an additional 2” of the wax extended past the trailing edge. You can get the sheet wax from MSC Direct here (A cheaper alternative is to cut up cereal boxes and spray tack those on, then srap tack on a layer of plastic film).

If the wax is not the kind with adhesive on its back then use 3m 77 spray tack to get it to stick to the daggerboard. Make sure you do a very clean job of applying the wax keeping the joints between sheets as tidy as possible. Mask off around the wax to keep things tidy. Then apply a couple of coats of wax mold release over the top to make sure everything releases nicely.

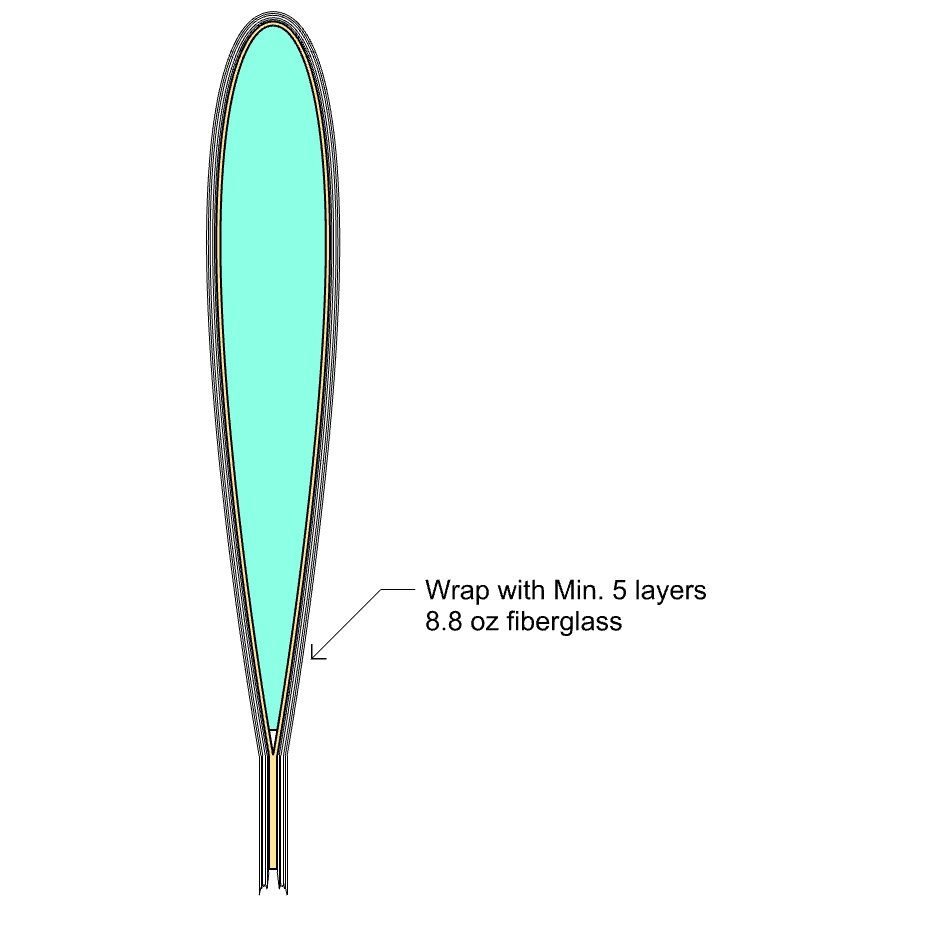

Making the Daggerboard Trunk. The first thing is to apply a surface coat on the wax— this will act as a wear-resistant coating that the daggerboard will slide on. Mix up epoxy with 5% by volume of graphite powder. Apply 2 coats using a brush and wait a few hours between coats for the epoxy to set up into a green stage. Once the second coat is cured to a green stage, drape a layer of 8.8oz fiberglass over the mold area and saturate it with epoxy. Use a squeegee and/or roller to make sure the fiberglass is laying down flat without any air bubbles or dry spots. Move directly to applying a second layer of glass also wetting out with epoxy and squeegee to lay flat. Repeat till you have at least 5 layers of 8.8 oz glass covering the mold surface. Wait till fully cured.

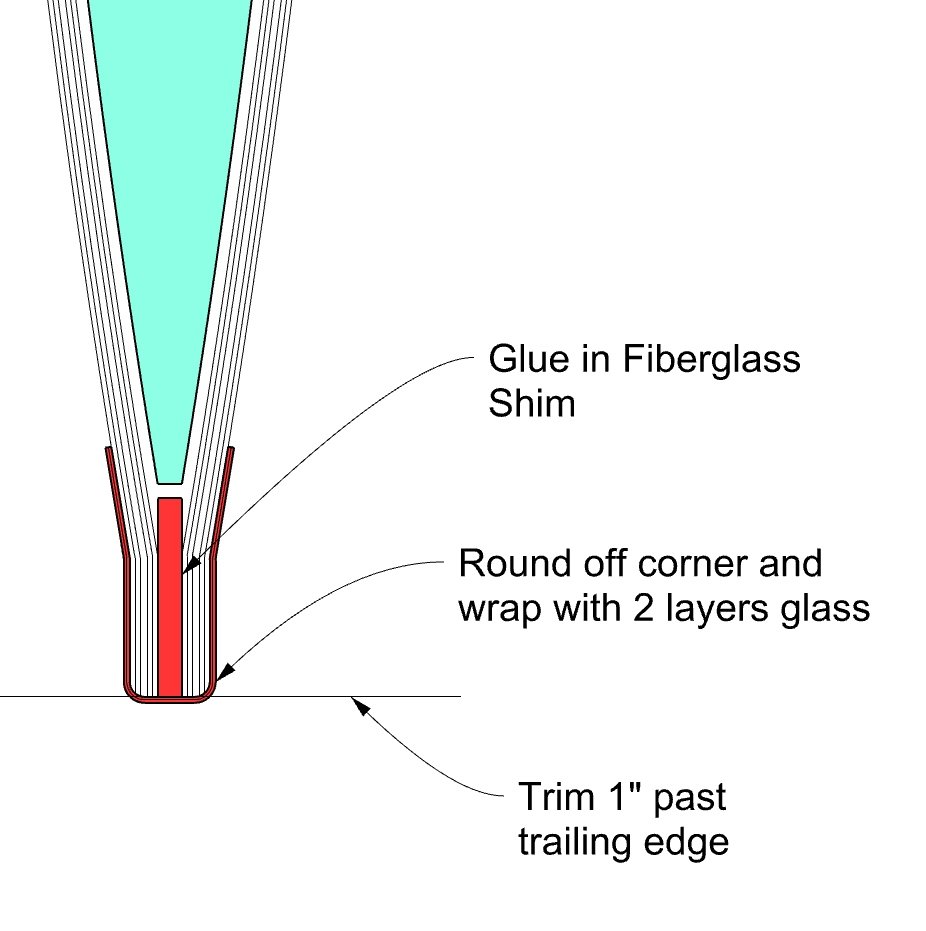

Removing the Trunk from wax surface. Carefully draw a line that is 1” past the trailing edge of the daggerboard. Cut the fiberglass at this line — It is ok to trim the wax also. Use some wedges in the trailing edge to pry the fiberglass away from the wax and daggerboard. It should release from the wax and you should be able to slip the trunk off of the daggerboard at this point. Remove the wax from the daggerboard and clean up the surface. Prepare a 1/8” thick shim strip to go into the trunk. This strip should ideally be made from G10 or some fiberglass sheet stock that is the right thickness. The inside edge of this needs to be straight and smooth as the daggerboard will slide on this. Carefully glue in the shim making sure not to get excess epoxy into the trunk. Use light spring clamp pressure to clamp together till the epoxy cures. Once cured clean up the edge, sand/prep the surface, and put some nice radii on the corners. Laminate 2 layers of fiberglass over this joint.

Post your comment on this topic.

Brandon wrote: Jul 17, 2024

The daggerboard trunk is best installed with the boat upright and level on its build jig. This makes it a lot easier to get the alignment correct. You can do this before rolling the boat and glassing the bottom or after glassing the bottom.

Kurt wrote: Jul 17, 2024

Could the Daggerboard trunk be constructed and installed before the bottom is laminated as you indicate with the centerboard trunk? If so this step is out of sequence. Thx