You can change the Speed Control Method between Open Loop and Closed Loop

Closed Loop

Closed Loop speed control utilizes a proportional – integral (PI) algorithm to regulate MDR speed. When enabled, the module motor control processor accepts the input from the Hall Effect sensors to measure rotor speed and will adjust the motor output accordingly to attempt to regulate speed. The value entered is in percent of the motor’s rated speed. Closed Loop speed regulation can be used for applications where you need to maintain constant speed with varying carton weights. The default setting is for Closed Loop to be enabled.

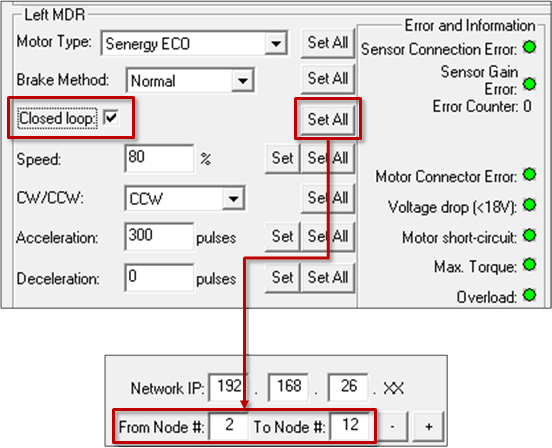

| Checking the Closed Loop check box enables Closed Loop speed control method. You can also use the Set All button to set the selected speed control method for each motor in the From Node # / To Node # boxes. In this example the Left MDRs from nodes 2 thru 12 will each get the same Speed Control Method speed setting. |

|

Open Loop

Open Loop speed control does not utilize any such feedback to regulate speed. The value entered is the percent PWM waveform (or “throttle”) that is output to the motor and the actual rotor speed will fluctuate depending on the mechanical loading on the motor

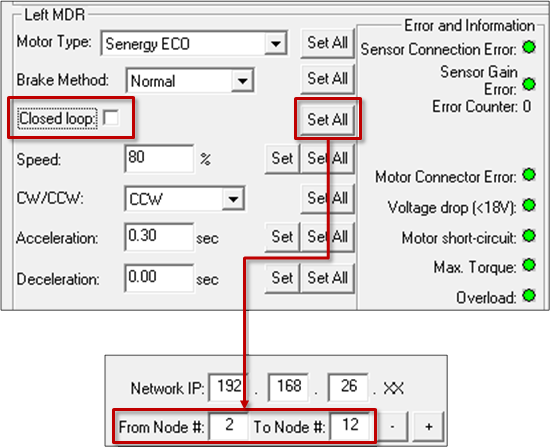

| Unchecking the Closed Loop check box disables Closed Loop speed control method and enables Open Loop speed control method. You can also use the Set All button to set the selected speed control method to each motor in the From Node # / To Node # boxes. In this example, all of the Left MDRs from nodes 2 thru 12 will each get the same Speed Control Method speed setting. |

|