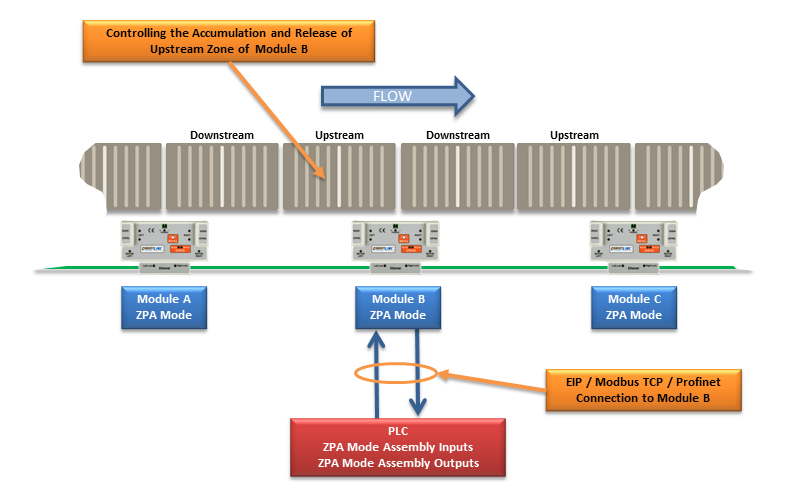

Here is a typical arrangement of an upstream or downstream zone on an ERSC in ZPA mode that is not the most upstream or most downstream zone in a given network. This example will show how to cause a Carton to accumulate, how to detect a Carton has arrived, how to write tracking data, and finally how to release the Carton. For this example, the PLC must establish ZPA Mode Assembly Input/Output connections to Module B as shown

- Upstream Zone Example

First, let’s assume we want to accumulate any Carton that arrives on the upstream zone of Module B. With the PLC:

- Set bit 0 in Accumulation Control for Local Upstream Zone register to instruct this zone to accumulate any Carton that arrives.

- Monitor Arrival Count Local Upstream Zone and Departure Count Local Upstream Zone registers. On the leading edge when these two values become not equal, the PLC knows there is a new arrival. Note that as long as a Carton is physically occupying the upstream zone, these two values will not be equal.

- Upon a successful arrival of a Carton in the upstream zone, then tracking data in Current Upstream Zone Tracking Word 1 and Current Upstream Zone Tracking Word 2 will be valid for the newly arrived Carton.

- The PLC may then decide that this tracking data is to be updated. The PLC can then write new tracking data to registers Set Local Upstream Zone Tracking Word 1 and Set Local Upstream Zone Tracking Word 2

- When the PLC is ready to release the Carton in the upstream zone, it should read the value in the Current Release Count for Upstream Zone register, add 1 to this value, and then write this new value to Release and Accumulate on Next Arrival for Local Upstream Zone register. When Module B sees this new value in this register, it will release the Carton in the upstream zone and automatically accumulate the next new Carton that arrives. Please note that if the downstream conditions from Module B are full when this new value is written, Module B will remember that it was instructed to release and will release the Carton when downstream conditions become clear without any further signal from the PLC.

- The PLC can detect when the Carton has departed the sensor on Module B upstream zone by examining the values in Arrival Count Local Upstream Zone and Departure Count Local Upstream Zone registers. On the leading edge of when these two values are equal, the PLC will know that the Carton has departed the zone sensor in Module B upstream zone.

If the PLC wants to cancel the accumulation control for Module B upstream zone:

PLC can reset bit 0 in Accumulation Control for Local Upstream Zone register. This will signal Module B to release any Carton accumulated and not accumulate the next Carton that arrives at Module B upstream zone.- Downstream Zone Example

First, let’s assume we want to accumulate any Carton that arrives on the upstream zone of Module B. With the PLC:

- Set bit 0 in Accumulation Control for Local Downstream Zone register to instruct this zone to accumulate any Carton that arrives.

- Monitor Arrival Count Local Downstream Zone and Departure Count Local Downstream Zone registers. On the leading edge when these two values become not equal, the PLC knows there is a new arrival. Note that as long as a Carton is physically occupying the downstream zone, these two values will not be equal.

- Upon a successful arrival of a Carton in the downstream zone, then tracking data in Current Downstream Zone Tracking Word 1 and Current Downstream Zone Tracking Word 2 will be valid for the newly arrived Carton.

- The PLC may then decide that this tracking data is to be updated. The PLC can then write new tracking data to registers Set Local Downstream Zone Tracking Word 1 and Set Local Downstream Zone Tracking Word 2.

- When the PLC is ready to release the Carton in the downstream zone, it should read the value in the Current Release Count for Downstream Zone register, add 1 to this value, and then write this new value to Release and Accumulate on Next Arrival for Local Downstream Zone register. When Module B sees this new value in this register, it will release the Carton in the upstream zone and automatically accumulate the next new Carton that arrives. Please note that if the downstream conditions from Module B are full when this new value is written, Module B will remember that it was instructed to release and will release the Carton when downstream conditions become clear without any further signal from the PLC.

- The PLC can detect when the Carton has departed the sensor on Module B downstream zone by examining the values in Arrival Count Local Downstream Zone and Departure Count Local Downstream Zone registers. On the leading edge of when these two values are equal, the PLC will know that the Carton has departed the zone sensor in Module B downstream zone.

If the PLC wants to cancel the accumulation control for Module B downstream zone:

PLC can reset bit 0 in Accumulation Control for Local Downstream Zone register. This will signal Module B to release any Carton accumulated and not accumulate the next Carton that arrives at Module B downstream zone.