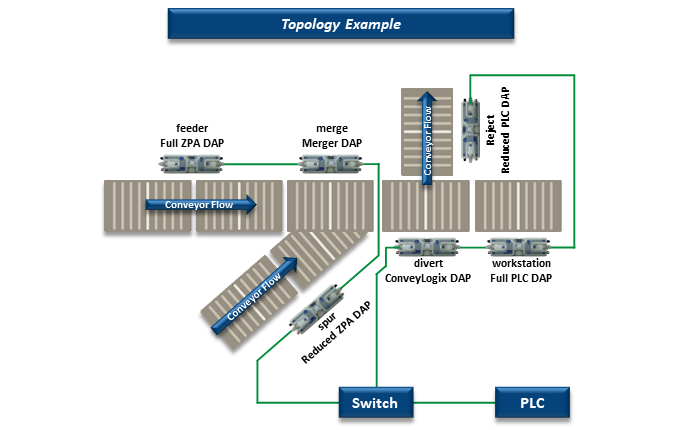

An example of a conveyor layout is a great way to illustrate the Integrated PLC Topology Configuration method.

| Module Mode | I.P. Address | DAP from Hardware Catalog | Profinet Name |

|---|---|---|---|

| Full ZPA | 192.168.0.20 | ConveyLinx-Ai in ZPA mode | feeder |

| Full ZPA with Merger | 192.168.0.21 | ConveyLinx-Ai merger | merge |

| ConveyLogix Interface | 192.168.0.22 | ConveyLinx-Ai in PLC mode with ConveyLogix | divert |

| Full PLC Controlled | 192.168.0.23 | ConveyLinx-Ai in PLC mode | workstation |

| Reduced ZPA | 192.168.10.20 | ConveyLinx-Ai in reduced ZPA mode | spur |

| Reduced PLC Controlled | 192.168.15.20 | ConveyLinx-Ai in reduced PLC mode | reject |

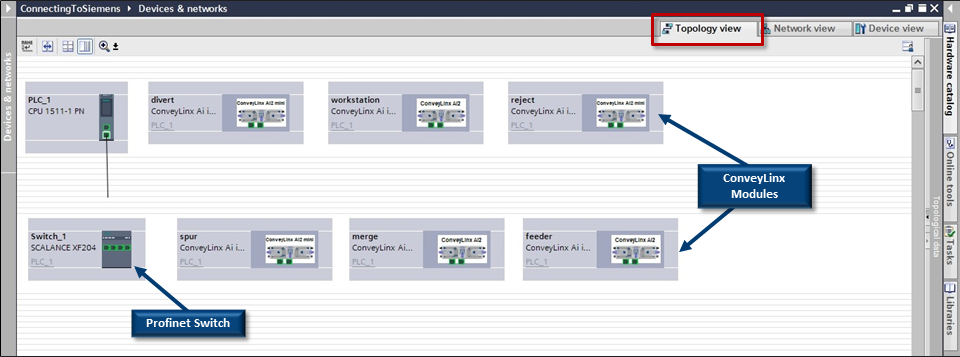

For this example, add these to your network in the same fashion as described earlier in the Examples of Adding Modules section. Because our example is using a switch, you need to select a Profinet switch from the Catalog. In our example we selected a SCLANCE XF204 four port switch. Here is a view showing all the items added to our topology including the Profinet switch and ConveyLinx modules.

Connecting PLC and Switch

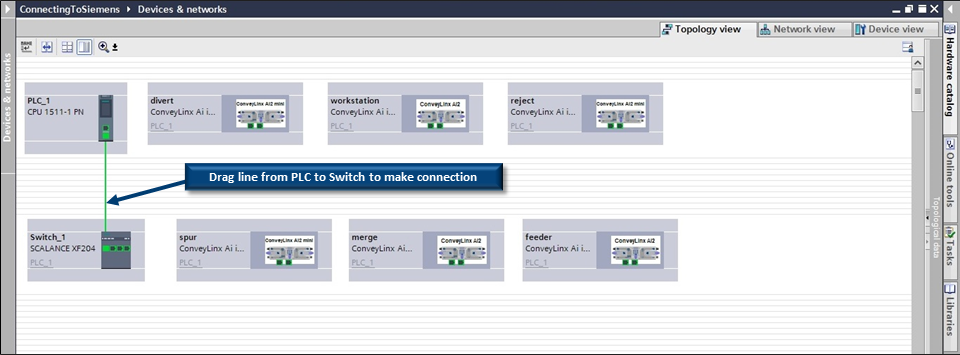

To make a topology connection, click and drag from the small connection square on the PLC to one of the ports on the switch.