Some conveyor applications may require that you be able to switch a defined quantity of zones between singulation and train release modes depending on operational conditions. Dynamic Release allows you to utilize Control Port signals to remotely perform this switching. There are two zones that require configuration in order to use Dynamic Release. The most downstream zone in the range of zones you wish to control is the Dynamic Release Control zone and the most upstream zone in the range of zones you wish to control is the Dynamic Release Termination zone. The Dynamic Release Control zone requires you to energize its Control Port Pin 3 signal to toggle between release modes. If the default release mode for the range is Singulation, then energizing Pin 3 will switch the range to Train. If the default release mode is Train, then energizing Pin 3 will switch the range to Singulation.

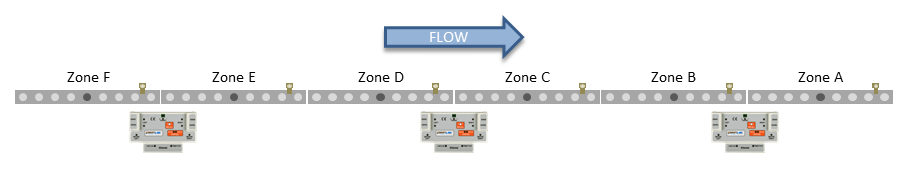

5 Zone Dynamic Release Example

For our example, we want to dynamically switch Zones A through E between Singulation Release and Train Release modes. All Zone’s default setting in our example is Singulation Release mode. Zone A will be the Dynamic Release Control zone and Zone E will be the Dynamic Release Termination zone. We will wire our signal to Zone A Control Port Pin 3 to to make this work. When we energize the signal, Zones A thru E will operate in Train Release Mode and when the signal is de-energized, Zones A thru E will operate in Singulation Release mode.

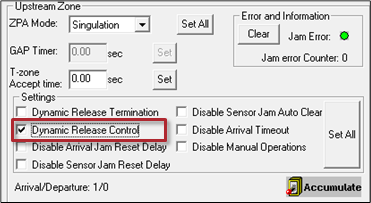

| You first navigate the main screen to the most downstream zone of the Dynamic Release range (Zone A). Clicking the Dynamic Release Control check-box will set this zone’s Control Port to look for Pin 3 energized to switch the release mode |  |

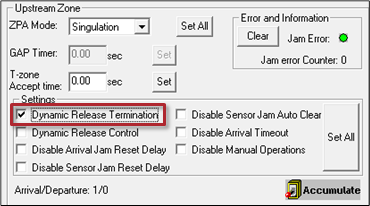

| Then you navigate the main screen to the upstream zone of the Dynamic Release range (Zone E). Clicking the Dynamic Release Termination check-box will set this zone as the “termination” of the Dynamic Release range |  |