The Flex Zone feature is enabled by default when you perform the Auto Configure Procedure. There can be certain situations such as higher speed applications and/or applications where a large percentage of cartons are at a length very close to the zone length where a “false triggering” of a flex zone condition can occur. In these situations, when product needs to accumulate, you may see several zones unoccupied because of this false triggering. For these applications where accumulation density is paramount, you can disable Flex Zone to eliminate this false triggering situation.

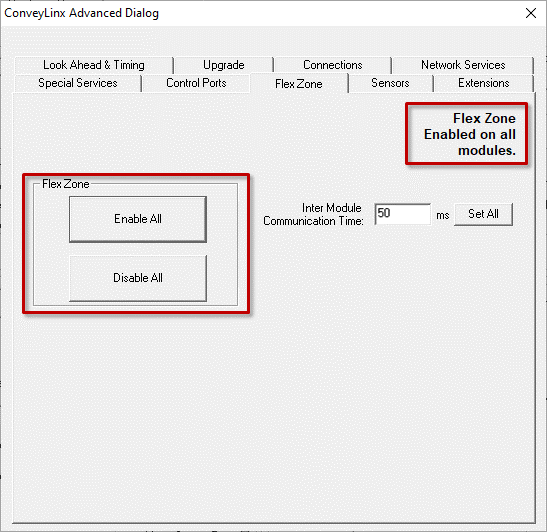

!Please note that Flex Zone function has to be enabled or disabled for the entire Subnet. It cannot be disabled or enabled on a per zone basis or for a group of zones within the same subnet.

| Click the appropriate button to either Disable or Enable Flex Zone based upon the subnet’s current status as indicated. Because this function applies to all modules in the Subnet, it does not matter what module you were connected to when you invoked the Advance Dialog in order to disable or enable Flex Zone |

![]() |

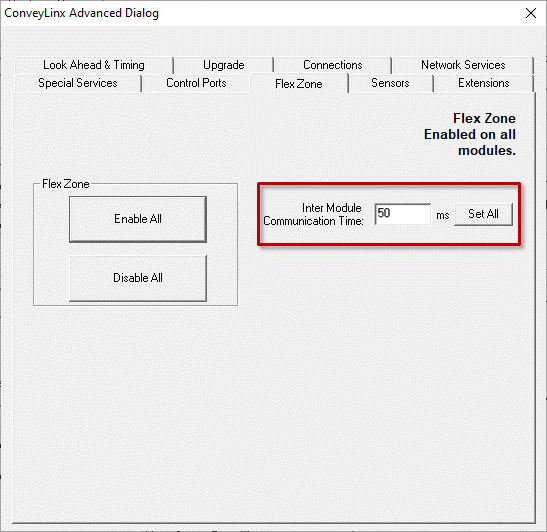

Inter Module Communication Time

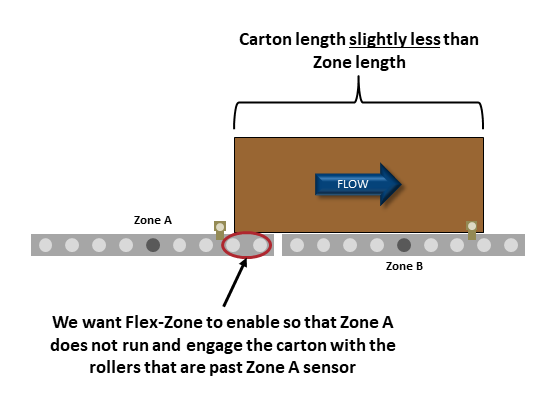

The Inter Module Communication Time value is used to adjust the behavior of the Flex Zone operation. In situations where carton lengths can be close to the length of the zones (i.e. distance between photoeyes), you may want to adjust Flex Zone operation so that it either engages or not in these situations.

|

Typically there are one or two driven rollers past the sensor in a Zone. If you have cartons that encroach upon these rollers when accumulated in the downstream zone, you may want Flex Zone to engage so that the next upstream carton will not enter the zone (Zone A in the example), thus not running these rollers underneath the accumulated carton. |

|

|

|

|

| The value entered is in msec and it can be thought of as an amount of time added to the logic after the trailing edge of the sensor in order to simulate increasing the carton length. Please note that this value will be set the same for each module in the Subnet. |

![]() |

*Please note this value has nothing to do with speeding up or slowing down the actual speed of communications between modules