Power and Electrical

The following is required from the customer:

| SR011 | UL/CSA, North America | CE, Europe |

|---|---|---|

| MODEL | -01 | -02 |

| Power | 240VAC / 3ØΔ / 30A | 400VAC / 3ØY / 25A |

| Receptacle | ABB430R9W | ABB532R6W |

| Connector | ABB430C9W | ABB532C6W |

| Inline Drain Pump | 120VAC / 15A | Selected by Customer |

The following is supplied with VORSA 500:

| SR011 | UL/CSA, North America | CE, Europe |

|---|---|---|

| MODEL | -01 | -02 |

| Plug (on Machine) | ABB430P9W | ABB532P6W |

Plumbing and Drainage

The VORSA 500 includes 3 plumbing ports on the back of the machine.

- FILL: auto-fills the chamber with fresh water. This function will typically be used for cleaning the machine periodically.

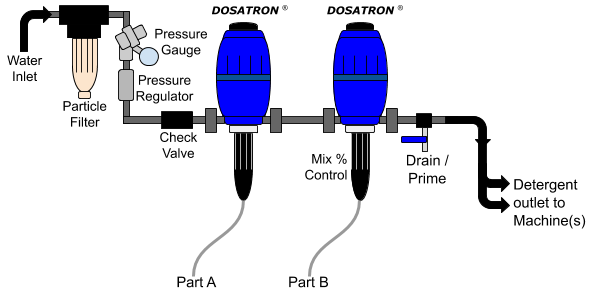

- DOSE: auto-doses the chamber with a ratio of water and detergent. The detergent is dosed into the machine via a DOSATRON® (included) manifold from 5-gallon buckets.

- DRAIN: provides a hook-up for inline pump

|

| Example Dosatron Configuration |

External Plumbing Requirements

| Function | Required from Customer |

|---|---|

| Dosatron inlet | Municipal Water Supply |

| FILL inlet | Municipal Water Supply |

| DRAIN outlet | Waste Container* |

| VENTILATION outlet | 4” duct hose (10 cm) and 30 CFM ( vacuum) |

| Note: Connect a splitter to municipal water to supply both the Dosatron and FILL inlets |

Facility and Floor Requirements

Operating Environment Requirements:

- Temperature: 15°C to 27°C (60°F to 80°F)

- Relative humidity: 0% to 80%.

- Maximum altitude: 10,000 feet (3,048 meters)

- Pollution Degree 2

- Overvoltage Category II

- Sufficiently sized doorways to transport the machine from loading dock to permanent installation location.

- Smooth, level flooring. The VORSA 500 must be placed on a level floor.

- Sufficient space in installation location for VORSA 500 and operator to maneuver around the machine and access master disconnect switch during normal operation.

- Locate and operate the unit at least 6 inches (0.15m) from any wall from all enclosure sides

- Installation area should be spacious and well ventilated.

- Power disconnects, plumbing, air, and emergency equipment should be installed in the same room as the VORSA 500.

Ventilation

PostProcess Technologies detergents are specifically formulated for maximized 3D printed support removal efficiency. Specific ventilation requirements can vary widely due to the local, state, and federal regulations, size of the install room, and existing ventilation (positive or negative).

To meet safety and environmental requirements, it is required that the post printing operations using PostProcess’ VORSA and chemistry solutions have ventilation that is exhausted. Make up air should be provided from the facility where the equipment is located.

It is recommended that customers performing post printing operations have or consult with a responsible environmental health and safety person (such as an Industrial Hygienist) to determine and verify meeting environmental, health, and safety (EH&S) requirements.

PostProcess can provide the recommended ventilation requirements for each of our solutions as well as recommendations for ventilation consultation and EH&S / Industrial Hygienists.

The VORSA 500 is equipped with a ventilation duct at the top rear of the machine. The customer is responsible for providing any ventilation ductwork prior to installation. It is recommended that the equipment be located in a well-ventilated room. Connecting the blower exhaust to a ducted system to remove the exhaust from the room is required.

For more information on the safe use of PostProcess detergents refer to the SDS for the specific detergent used.

Post your comment on this topic.