Heater Maintenance

The Heater Maintenance screen is used to set the amount of VORSA 500 run time before the heater is taken out and cleaned.

|

| Heater Maintenance |

The Heater Maintenance Scheduling slider bar sets the number of operational hours that the VORSA 500 should run before the heater is cleaned. The number of hours can be set by pressing the desired number or by using the + / – buttons. Once the heater has been cleaned, press the RESET SCREEN SCHEDULE button to reset the Remaining Optimal Usage countdown. It is recommended to set the Heater Maintenance Timer at 200 hrs.

The Remaining Optimal Usage Gauge displays the remaining percentage of heater life in hours. As the time counts down the gauge will turn to yellow and then red when it is time for heater cleaning.

Refer to Routine Maintenance for details on performing Heater Maintenance.

Chamber Screen Maintenance

The chamber screen refers to the mesh screen that is positioned beneath the lower spray rack inside the processing chamber. To maintain the process efficiency of the VORSA 500, it is important to keep the screen free of support material and the other residues that may impede the flow of detergent within the system.

|

| Chamber Screen Maintenance |

The Screen Maintenance Scheduling slider bar sets the number of operational hours that the VORSA 500 should run before the filter screens are cleaned. The number of hours can be set by pressing the desired number or by using the + / –. It is recommended to set the Chamber Screen Maintenance Timer at 200 hrs. Once the filter screens have been cleaned, press the RESET SCREEN SCHEDULE button to reset the Remaining Optimal Usage countdown.

The Remaining Optimal Usage Gauge displays the remaining percentage of filter screen life in hours. As the time counts down the gauge will turn to yellow and then red when it is time for screen cleaning.

Refer to Routine Maintenance for details on performing screen maintenance.

Tank Screen Maintenance

The Tank Screen Maintenance screen represents the reservoir tank that can be accessed via the back panel of the machine.

|

| Tank Screen Maintenance |

Refer to the Routine Maintenance section for more information.

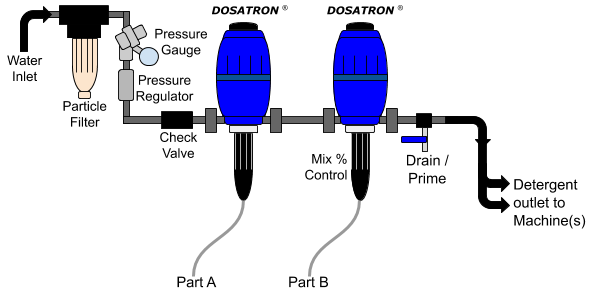

Dosatron Maintenance

The Dosatron Maintenance screen is used to set the amount of VORSA 500 run time before the Dosatron particle filter (see below) is taken out and cleaned.

|

| Dosatron Diagram |

|

| Dosatron Maintenance, Page 2 |

- The Dosatron Maintenance Scheduling slider bar is utilized to select the number of operational hours that the VORSA 500 should run before the Dosatron particle filter is serviced. The number of hours can be set by pressing the desired number or by using the + / – buttons. Once the filters have been cleaned, press the RESET DOSATRON SCHEDULE button to restart the Remaining Optimal Usage countdown. It is recommended to set the Dosatron Maintenance Timer at 100 hrs.

- The Remaining Optimal Usage Gauge displays the remaining percentage of filter screen life in hours. As the time counts down the gauge will turn to yellow and then red when it is time for filter screen cleaning.

- Refer to the Clean Dosatron Particle Filter instructions under the Routine Maintenance section for more information.

Post your comment on this topic.