Automotive.One is a module which not only supports the special needs of the suppliers, but also enables a more global view on requirement processing in the form of scheduling agreements. The business processes in the ERP-module are represented from the point of view of the processing with an individual purchase order. This module expands the representation of the business processes of SAP Business One by the serial view. The specific business processes of the suppliers are:

- forecast delivery schedule()

- JIT deliver schedule()

- JIS calls()

- delivery note transport data()

- goods tag()

- forwarding order()

- credit memo procedure()

- invoicing procedure()

- external service providor()

This module not only displays the issues of the supply chain (supply chain management), but also the areas sales() and purchase() in the serial view.

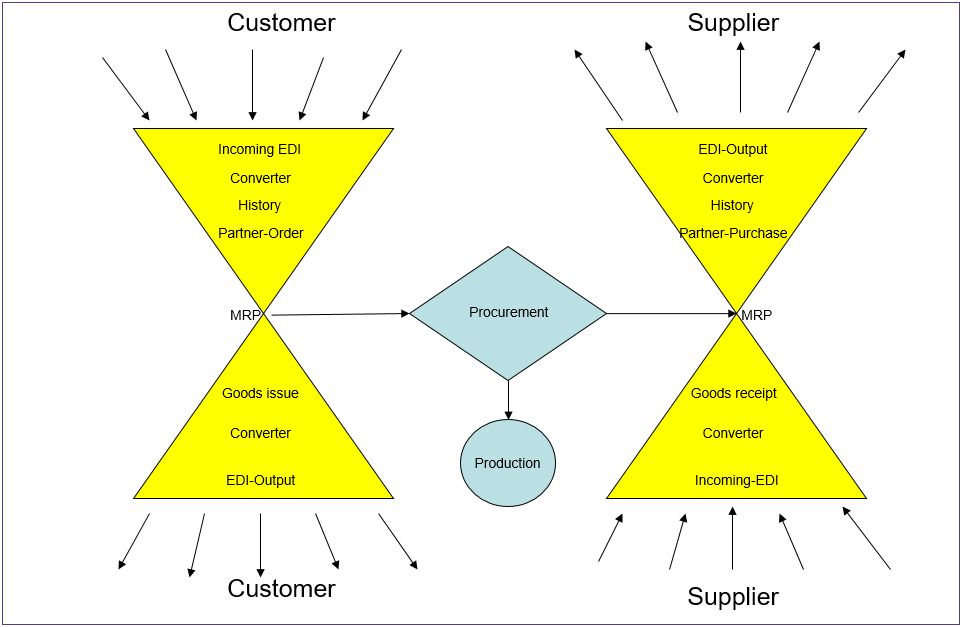

The communication between vendor and customer or customer and vendor generally takes place via electronic data interchange (EDI).

To enable communication between computers, there have to be regulations. These rules were established by varying institutions. The following institutions are of importance:

- Association of the Automotive Industry(VDA)

- Electronic Data Interchange For Administration, Commerce and Transport (EDIFACT)

- Organisation for Data Exchange by Tele Transmission in Europe (ODETTE)

- American National Standard Institute (ANSI)

Moreover the module administrates the scheduling agreements and provides the requirements for the MRP (material ressources planning). It organizes distribution, generates open items (OI), creates distribution papers and provides the customer with distibution data.

In the purchase-sector the module generates forecast delivery schedules for the vendors as a function of the disposition assistant (MRP). It administrates the scheduling agreements and executes the goods receipt in function of the partner purchase orders.

As mentioned beforehand, the module Automotive.One not only satisfies the automotive supplier’s interests, but also expands the administration of individual orders by scheduling agreements (many allocations (date, quantity) over a long period of time).

The view of individual orders:

In the picture above the individual orders are represented by green bars. The individual orders all have a requirement which has to be met by a specific delivery date. The respective individual orders have no connection among one another. The sequence of completion of the orders is of no importance, that means you can simply complete one in the future without completing an older one. The degree of fulfillment is irrelevant as well. The deliveries are represented by a brown bar. A single order can have a exceeding or shortfall of deliveries without affecting the other individual orders.

The view of scheduling agreements:

A scheduling agreement is a requisition note over a long period of time. The single requirements at a specific point in time are defined as an allocation (of a scheduling agreement) – they are represented by the green bars. The allocations can be daily, weekly or monthly requirements. There can be two more parameters transmitted in a scheduling agreement: backorder and immediate requirements (painted red). The backorder and immediate requirements are to be handled as fast as possible compared to the allocations. In a forecast delivery schedule there are two more parameters transmitted: cumulative quantity recieved (CQR) and the date of the last delivery (boundary date). The CQR represents the sum of goods receipts (light blue color) at the customer which accumulated in the space of time from the “date of zero position” to the “boundary date”. The boundary date generally represents the date of the MRP-run at the customer. If the diagram is expanded by another cumulative quantity (cumulative quantity delivered(CQD)), the scheduling agreement can appear as follows:

The CQR (cumulative quantity recieved) represents the sum of deliveries (yellow color) which accumulated in the space of time from the “date of zero position” to the current date.

If you add the backorder/immediate requirement to the CQR now and the call quantity to every call date, you will recieve a requirement curve.

If you subtract the CQD from the requirement curve, you will get the yet to be delivered quantity.

Post your comment on this topic.