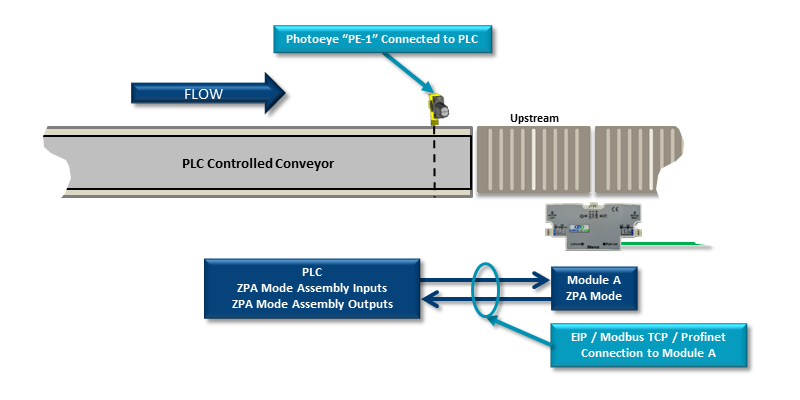

This example describes how to use a PLC to control the “wake-up” and passing of tracking data to the most upstream zone of a ConveyLinx controlled conveyor

![]()

For this example, the PLC must establish a connection with Module A. When PLC is ready to transfer a Carton from the PLC controlled conveyor to the Upstream Zone of the MDR Conveyor, the PLC logic must:

- Write a “4” into Set Status for Upstream Induct register. This will cause the upstream zone of Module A to run to accept Carton.

- When Carton clears PE-1, write tracking data to Set Induct Tracking Forward Direction Word 1 and Set Induct Tracking Forward Direction Word 2

- When Carton clears PE-1, write a “1” to Set Status for Upstream Induct register. When Module A sees this register change to “1”, it knows that the tracking data written to Set Induct Tracking Forward Word 1 and Set Induct Tracking Forward Word 2 is valid and when the Carton reaches the sensor in its upstream zone, the tracking data will be correctly inducted

*Module A must see the Set Status for Upstream Induct register change from 4 to 1 in order to recognize the tracking data written to Set Induct Tracking Forward Word registers. If using the clearing of PE-1 to initiate the write of “1” the Set Status for Upstream Induct register in the PLC logic; the physical length of the Carton must be less that the distance between PE-1 and Module A’s upstream zone sensor because Module A inducts the tracking data upon the Carton arriving at its upstream sensor and if Set Status for Upstream Induct has not changed from 4 to 1, the tracking data will not be valid.

!If a value of “4” is in the Set Status for Upstream Induct register at the same time the Carton reaches the local upstream zone’s sensor; the local upstream zone will assume the Carton is physically longer than one zone and will invoke it’s on board Flex Zone logic and behave accordingly. Please refer to the ConveyLinx User’s Guide for description of Flex Zone operation. To reliably transfer tracking data and ensure single Carton induction to the local upstream zone, the PLC programmer must ensure proper use of the Set Status for Upstream Induct register

Post your comment on this topic.