INITIAL OPENING

- Unlock the Entrance Door

- In the event of any Security Breaches / Unlawful Entry, call Gardai and notify Operations Team – remain outside premises until Gardai arrive

- Disarm the Alarm

- Switch on the lights necessary for pre-opening procedures

- Put on Uniform (including Hair Nets, hats and remove requisite jewellery if applicable)

- Clock-In.

- Covid 19: take infrared thermometer reading and record on Temperature Screening Record (if applicable)

- Check weather [YR online App.] Re: 10 Commandments to estimate how busy the day will be

- Place / collect any Orders that may be necessary e.g. Milk, Fruit, Sysco, Gino’s Warehouse

- Wash your hands (at commencement of the day and regularly throughout the day – every 20 minutes)

- Identify/prioritise duties to other team members (if additional employees have been rostered for opening shift)

- Review Roster, factor in weather and call-in (or cancel) shifts if and when necessary

- List products necessary for the day and source whatever is needed from the Stock Room, Back-Up Freezer or Back-Up Chiller and bring necessary stock required for shop floor

- Ensure all bins are empty with clean bin-liners

GELATO STATION

- If Gelato Maker Manager, Turn on Blaster, source requisite ingredients & refer to Gelato Makers’ ‘Bible’

- Clean Gelato Display Refrigerators [empty condensation trays if applicable]

- Switch on Gelato Display Refrigerators ensuring blank trays fill the entire display space

- Set Gelato Refrigerators to correct temperature (between -12 ̊C ↔ -14 ̊C [Winter]; -14 ̊C ↔ -16 ̊C [Summer])

- Display Refrigerator fronts, tops and backs are clean and free of marks

- Check that Spoon Holders are clean, topped up and placed in position

- Check Napkin Dispensers are clean, full and placed in position

- Check Cylindrical Cone Displays are clean, stocked up with cones and placed in position

- Display sufficient Gelato Tubs in Cylindrical Display or designated area.

- Ensure Flake® Jar and all Toppings / Dips Jars are clean and full and placed in position. (real Flake® chocolates are not displayed in view of the customer)

- Stock up: Small & Large Gelato Take Home containers and cardboard Gift Boxes.

- Ensure all Gelato put on Display is Tagged correctly and includes a Special of The Day & Sorbet Special of the Day

- Ensure that there is a variety of colours between Gelato displayed i.e. do not put all the chocolate flavours side-by-side. Contrast the different colours to make the display look more eye-catching.

- Blank Trays are used symmetrically on the left and right side of Display Fridges & replaced as Gelato is brought out

- Check Whipped Ice Cream machine topped up (where applicable)

CREPES & WAFFLES STATION

- Fresh Crêpe Mix (or sufficient in-date mix) is prepared/available

- Ensure Fresh Waffles Dough is prepared if needed. Remove frozen Waffle Dough Balls, required to meet daily demand, from Back-Up Freezer [<-18⁰C] and place into Chiller [0⁰C – 5⁰C]- frozen Waffle Dough Balls must be left to thaw out in the chiller for a minimum of 20 minutes before being cooked for customers.

- Ensure fresh toppings are in-stock / sourced and prepared e.g. strawberries sliced and bananas available. Make sure you have enough sliced strawberries for the day to prevent any delays in serving customers. (Buy/Order strawberries and bananas if stock is low).

- Ensure Nutella® Dispenser Squeeze Bottles are filled and Nozzles are clean & unobstructed

- Turn on Nutella® Warmers [usually 80 ̊C, for 15 minutes then lower to 70 ̊C]

- Ensure all Toppings and Sauces in the Crepe / Waffle Station are topped up and containers are clean.

- Turn on Waffle Machine [180⁰C]

- Turn on Crepe Machine [170⁰C]

- Work Stations equipped with necessary tools i.e. Crêpe & Waffle preparation equipment

- Prepare enough napkins, knives, forks, spoons, crepe holders, waffle trays, take away boxes, take away bags and cup carry trays for the day.

- Check Cream Dispenser has fresh cream

- Check Icing Sugar container is full

Coffee / Hot and Cold Beverages Station

- Turn on the Coffee Machine & ensure Coffee bean Grinder is ½ topped up

- Top up Coffee Cups and Lids if required (Coffee Cups, Hot Chocolate Cups, Flat White Cups and Lids)

- Top up wooden stirrers and sugar sachets

- Bring Fresh Milk to Service area Chiller if required.

- Switch on bottle warmer with Callebaut® Chocolate Buttons [70⁰C] & ensure bottle is full (for Hot Chocolate)

- Prepare enough Milkshake Mix required for the day

- Stock up: Milkshake Cups, Lids and Straws in serving area

- Check there are small spoons for Affogato

- Check Coffee Syrups are available and pump dispensers are clean

- Check Minerals Refrigerator is full and ‘Slushie Machines’ are topped up

FINAL PREPARATION FOR OPENING

- Check Till receipt rolls and Credit Card Machine receipt rolls

- Bring Floats for Cash Registers from Safe with sufficient coin denominations

- Check Shift Report on EPOS Terminal is 0.00

- Process a ‘Z-Reading on Credit Card Machines’ – retain receipt and give to manager if read is not 0.00.

- Ensure ‘Front of Outlet / Exterior is clean and appealing to customers – especially front area / display window

- HAACP Charts: Conduct Temperature Check and fill in all Temperature Charts & applicable Cleaning Charts

- Ensure Floor, Skirting Boards, Windows, Mirrors, Tiles, Mirrors, Cabinets, Display Units & Counter Tops and Metal Surfaces are cleaned / polished

- Turn on Music, Marketing Screens, all Sales Area Lights(different colours in flash mode)and Display Fridge Lights (including Minerals Fridge)

- Take out and display any external pedestrian Display Boards (if applicable)

- Fill out any Specials on Chalk Board if applicable

- Covid 19 Policies: Ensure there is Hand Sanitiser available for customers and staff. Ensure the cleaning / sanitisation charts are followed.

- Open Entrance / Shutters and commence trading

MID SHIFT: DURING THE DAY

- Primary focus: Service [aside from attending to an immediate high-risk issue or hazard] serving the customer with the highest standards of courtesy is our number one objective.

- Whatever task/duty one is engaged in, Managers, Assistant Managers, Supervisors, Gelato-Makers and General Operatives must prioritize attending to customers’ orders, needs and, requests and offering them assistance.

- No Tip Jars are kept on the serving counter [Ireland]

- Greet customers in a welcoming manner

- Offer samples to undecided customers

- Engage customers, particularly if it is quiet. Make suggestions as to what are popular flavors or what is your favorite flavor

- Go through the Allergen Chart with a customer if there are allergen or food intolerance queries

- Offer ‘Large’ or ‘Regular’ to customers ordering Gelato (explain: 3 flavors with a Large & 2 flavors with a Regular

- Never handle a cone with your hand – use a napkin or glove

- Always mix pasta and variegato when scooping a portion of gelato.

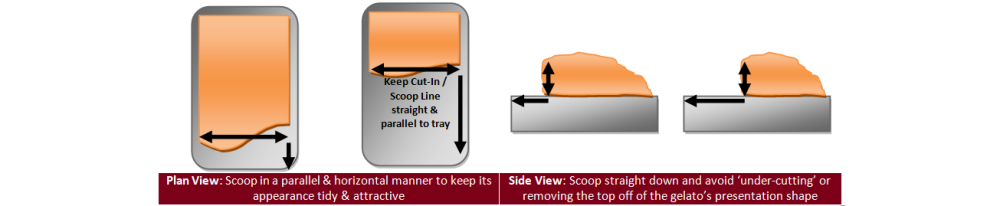

- When scooping from the Napoli Tray, scoop Gelato as cleanly as possible and work in parallel and vertical manner.

- Do not ‘squash’ the Gelato into a cone or tub – slide spoon parallel to cone or tub to form a peak/spike.

- Do not weigh cup or cones on a scale in front of a customer (unless you are checking a Take Home tub)

- Offer ‘Toppings’ on the Gelato

- Always keep Serving Spoons upright in the Gelato Trays – this makes the display much more appealing and prevents handle to product contamination

- Do not use phones in front serving area – it is offensive to customers & unprofessional.

- When it’s quiet, offer samples to passing customers in front of the outlet

- Notify Gelato Maker / Manager if any flavor in the Display Freezer is running low.

- Notify Gelato Maker / Manager if any Gelato on display does not look good or is ‘slumped’ – so it can be refreshed.

- Notify Manager / Supervisor if any stock levels in the shop are running low.

- Notify Manager / Gelato Maker is Gelato in Display freezer is too hard or too soft so that they can adjust the cabinet temperature

- Clean As You Go: Particularly in the front of the shop, any spills or mess occurring must be cleaned immediately.

- Eye on Detail: Floor, Skirting Boards, Windows, Mirrors, Tiles, Mirrors, Cabinets, Display Units & Counter Tops and Metal Surfaces should be cleaned throughout the day

- The outlet/kiosk’s exterior must be clean = the first impression a customer is likely to form of the company.

- HACCP: Temperature & Cleaning Checks must be conducted and observed and recorded on the relevant charts.

- Preparation & Best Before Dates must be put on Crêpe Mix, Waffle Mix, milkshake mix, Base Mix, Fresh Cut Fruit and, any perishable product prepared on any given day Re: Day Dots Sheets

- Entries must be made on any relevant Records/Charts/ Day Dots Sheets.

- Keep ingredients containers, jugs and, bowls covered e.g. Milkshake mix, Crêpe Mix, strawberries

- When not serving, keep Display Freezer covers closed

- Front of Outlet Inventory: Top up Cones, Tubs, Napkin Dispensers, Crêpe Serviettes

- Ensure that there are sufficient assembled Waffle Trays.

- Ensure there are enough Greaseproof Paper sheets for Waffle Trays

- Top-up jars containing Toppings and Dips (e.g. Marshmallows, Sugar, Hazelnuts, Crushed Oreo®, Sprinkles, etc.)

- Top up Nutella® Dispenser Squeeze Bottles when required and clean nozzles to allow efficient dispensing.

- Top up ‘Slushie Machine’ and Whipped Ice Cream Machine (where applicable)

- Top up melted Callebaut®chocolate buttons Dispenser Squeeze Bottles when required and clean nozzles to allow efficient dispensing.

- Check, clean / refill Cream Dispenser if running low

- Ensure Milk Shake Machines are cleaned and dried – agitators/spindles and mixing cups.

- Waffle Dough, Crêpe Mix and, Base Mix levels must be monitored and batches should be prepared to satisfy forecasted demand.

- Wash hands every 20 minutes

- Keep uniforms as clean as possible

- ‘Walk Through’: Do a ‘walk-through’ of the outlet. Look at the Shop Frontage, Serving Areas, Display Fridges, Ceilings, Mirrors, Floors, Skirting and organize a tidy/clean-up to keep the outlet attractive and appealing to customers.

- Daily Quality Audit: ensure the Quality Audit is done daily and submitted before * 3:00 pm*. Delegate the task to all staff members so that they become familiar with all the Gino’s Gelato checks, policies, standards, and HACCP requirements.

- ‘Would I Buy It?’ [WIBI]: Put yourself ‘in the shoes’ of a customer and ask yourself whether they would purchase the products on display i.e. the Gelato in Display Fridge, demonstration Waffle/ Crêpe display.

- Labels/Tags on Gelato: Whenever fresh Gelato is brought to the Display Fridge; ensure they are labeled.

- Steam-Pipe [Espresso Machine]: When Coffee is prepared, ensure the SteamPipe is cleaned after every use.

- Ensure Hot Chocolate Machines are cleaned and dried – blender and mixing jar. Ensure the containers at the back are topped up with bottled water.

- ‘Chill-Chain’: minimize any time a product that needs to be chilled (or frozen) is left outside a refrigerator e.g. if bringing milk & cream from the backup chiller to do a base pasteurization, only bring it out when needed. When preparing Milk Shakes, tea, coffee – return the mix/milk to the chiller as soon as you have finished using it.

- Refrigerate strawberries as soon as possible after cutting or using them on Crepes/Waffles.

- Drip Dry / Avoid Idle Water: When washing Gelato Trays, Gelato Spoons, Equipment, Containers, Cutlery, etc. Dry with a clean green micro-fiber cloth and store them away as often as time permits to prevent bacteriological contamination.

- Pasteurizer & Gelato Making Machines: Managers and Gelato Makers must ensure that after the Gelato Base has been used up, or the Gelato Making Machine is ready for daily cleaning, a thorough washing should be conducted and a rinse-out is carried out using, Milton® Sterilizing Fluid.

- Once sterilized/disinfected, the interior of the Pasteuriser & Gelato Making Machine must be dried thoroughly (i.e. using a fresh Green Micro-Fibre Cloth) – If even a little water is left idle in machinery it can result in bacteriological contamination and we should consistently guard against this.

- Use Yellow Warning Signs when mopping the floor

- After mopping – empty dirty water and return mop and mop bucket to designated storage area.

CLOSING SHIFT

- Ensure End-of-Day HACCP Temperature and Cleaning Charts are filled in.

- Ensure the Gino’s Gelato Staff Facebook® ‘Closing Pictures’ have been uploaded.

- Delegate Team Members to effectively and efficiently complete closing duties, prioritize particular tasks where needed.

- General Cleaning: floors, surfaces, Display Fridges, tiles, skirting, units, cabinets, stainless steel surfaces (Ceilings and Lights should be cleaned at least on a weekly basis), etc.

- Clean the Coffee Machine with designated powder and follow instructions.

- Empty Coffee Bin Unit, clean and dry interior.

- Ensure Crêpe Machine surfaces and sides are cleaned (and that at least once a week a ‘deep clean’ is conducted using a Krampouz® Abrasive Stone).

- Ensure Waffle Machine is cleaned including the exterior top, sides, and bottom.

- Ensure Crêpe Machine is turned off

- Ensure Waffle Machine is turned off

- Ensure Milk-Shake Machine’s exterior, agitators, shafts, and mixing cups are clean and dry.

- Ensure the Hot Chocolate Machine’s exterior, blender parts, mixing jugs are clean and dry.

- Ensure the fresh cream in the Whipped Cream Dispenser is in-date – clean the nozzle tulip.

- Top-Up Nutella®Squeeze Bottles and clean dispensing nozzles.

Top-Up heated Callebaut® Chocolate Buttons Squeeze Bottles and clean dispensing nozzles. - Top-Up Toppings containers

- Empty Bins and put in new bin liners

- All Micro-Fibre Cloths must be rinsed thoroughly and stored in designated buckets/containers containing Chlorine Bleach for disinfection purposes.

- Empty Mop Bucket and rinse mop – allow to dry overnight.

- Store Gelato and cover with lids/cling-film (use sticker with the date and description for identification purposes before storing in Gelato back-up refrigerator)

- Clean all Napoli Serving Trays and ensure they are dried/racked in such a way as to prevent idle water to settle.

- Clean all Gelato Serving Spoons, mixing bowls, Pyrex jugs, empty Crepe Mix jugs, buckets, etc. Dry and put items in their place.

- Ensure interior of Refrigerators/Freezers are clean and that any products being stored overnight are In-Date/Un-expired. If any preparation is expired, ensure that they are recorded and disposed of.

- Ensure Pasteurizer Machine has completed its cycle and that the temperature of the Gelato Base is: 1⁰C – 5⁰C

- Close Cash Registers and process Credit Card Machine readings . Retain receipts. Do an ‘End-of-Day Banking’ reading and ‘Z’ reading on CC machine every night and keep with merchant copy CC Receipts to submit to Head office each week

- Process BlueChip End of Day Close data through laptop application.

- Report / record any ‘overs’ / ‘unders’ from the cashing up process to Management.

- Always check Till Floats are correct and put in coin denominations in the cash register tray necessary for the next day’s operations

- Always check the Safe Float and check your change breakdown –order from Cash Supplier /Bank if needed

- Complete Cash completion sheet

- Fill in Lodgment Slip and put into Lodgment Bag then seal

- Always ensure details are filled out accurately and completely on Lodgment Slips and Lodgement Envelopes

- Ensure all Cash is locked in Safe

- Leave Till Drawers open so would-be burglars know there is no cash in the registers and do not resort to damage

- Ensure all external leading doors are closed and all appliances that need to be turned off are off e.g. Waffle Machine, Crêpe Machine, Nutella® bottle Warmers, Iron, etc.

- Ensure all Refrigerators and Chilled Storage Rooms are properly closed and the relevant ones are operating.

- Ensure CCTV cameras are always left on

- Make sure all end-of-day cleaning duties are completed

- Ensure all lights that are turned off overnight are switched off

- Check all taps are off i.e. sinks & basins

- Set Alarm and lock premises securely

↓ To be updated & Edited [02-2022]

h2. Weekly Procedures

Cleaning Condensors etc

Cleaning whipped machine (if applicable)

Pull out machines on wheels and clean and mop behind once a week

Basic Rules

No blue jeans or white runners

No mobile phones to be used except in emergences

No standing around when not busy always look busy cleaning

Hair nets to be worn at all times

No nail varnish

Temperature sheets to be filled in every day

When not busy ask customers would they like a sample

If customer asks about a product be informative, offer a sample

if kiosk phone rings always serve customer first

Never tell a customer we are closed

Always come to work with a clean uniform

If a customer’s ice cream falls, replace it don’t charge

The following is a list of our Core Products.

These products should always be available in this store.

1. Mint Choc

2. Banoffee or Banana

3. Bubble gum

4. Chocolate

5. Cookies

6. Dolce latte

7. Ferrero.

8. Hazelnut

9. Kinder Bueno

10. Sorbet

11. Mr Nico/Snickers

12. Nutella

13. Stracciatella.

14. Strawberry Cream

15. Vanilla

16. Yoghurt

17. Diabetic Product (Wellness Line)

Below are products we will swap around

18. -watermelon sorbet 500 or Lemon 500

19. -whisky cream (baileys cream)

20. -white chocolate

21. -Apple Pie

22. -Banana

23. -caramel

24. -cheese cake

25. -cherry mania

26. -Cherry Yogurt

27. -dark chocolate (water)

28. -hello kitty

29. -mango cream

30. -Oreo

31. -Passion fruit Yogurt

32. -pistacchio (100%)

33. -rum and raisin

34. -Soja Strawberry

35. -Strawberry sorbet 500

36. -Strawberry Yogurt

37. -tiramisù

The Uniform is

Green Ginos T Shirt

Burgandy Cap

Hair net

White Coat / Apron if making gelato

Black Trousers

Black shoes/runners

Use basic knowledge when it comes to keeping your uniform clean, for example wear the apron when making ice cream. Always keep clean the part of the freezer where your T shirt will touch when leaning in to scoop Gelato. Etc.

Post your comment on this topic.