Work with variable material issue

In certain manufacturing processes, it may be necessary to manually enter the material consumption, because there is no mathematical relationship between material consumption and the final product.

This can also be the case in process production, where you have to to add material continually.

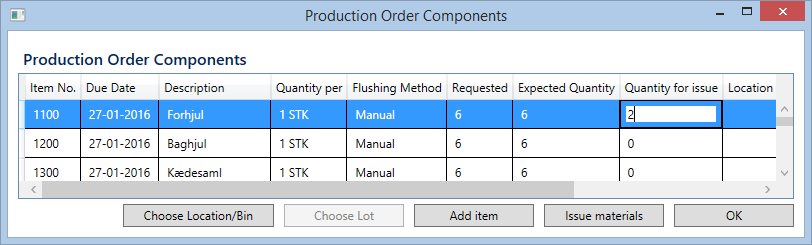

Therefore it is possible to manually enter the number / quantity of each product on the certain line, in the window “Material issue”.

The field ”Issued” is automatically updated, when material is issued via the function ”Issue material”.

There is also the oppurtunity to add a component, which is not a part of the standard of the BOM, via the function “Add component”.

The list of the items is displayed and the component in question can be selected. It is possible to sort the list in ascending or descending order, or in alphabetical order. Futheron you can search the number.

The selected item is now inserted in the BOM and the issued number has to be added:

Need more help with this?

NAVEKSA Help desk