*Distribution of actual job time across family order lines *

Examples of Calculations

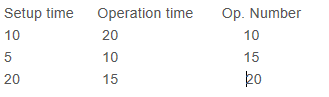

3 order operations which are running as a family order. Automatic completion is used (clock in /clock off). The following hours and quantity exist:

1. Calculation of the total estimated time (running hours x planned number) x number of orders (650). If the total time cannot be calculated because the total time is 0, the spent time is allocated evenly.

2. Finding of total time spent (e.g. 400).

3. The allocated, spent time of the operation: (Running hours x planned number / total planned time) * total time spent.

3.1 ((20 ×10) / 650) × 400 = 123

3.2 ((10 × 15) / 650) × 400 = 92

3.3 ((15 × 20) / 650) × 400 = 185

If the planned running hours are 0 (zero) or the planned numberis 0, the time spent is set to 0.

4. When calculating the number at partial reporting without number/quantity, the quantity is set to 0 (zero).

Real time spent per operation / running hours.

4.1 123/20 = 6

4.2 92 / 10 = 9

4.3 185 / 15 = 12

If the number is bigger than an order quantity, the number is set to the order quantity.

The setup is allocated in the same way. Partial reported time without quantity: Spent time is allocated in the same way as automatic completion (clock in/clock off).

Partially reported time without quantity: Time spent is allocated in the same way as the automatic reporting as completed (clocking in / clocking off).

Partial reported time with quantity (number): Calculation is made in the same way as the automatic completion reporting, just using the reported number, instead of the estimated quantity. The same is valid for the reporting of the final completion.

Need more help with this?

NAVEKSA Help desk