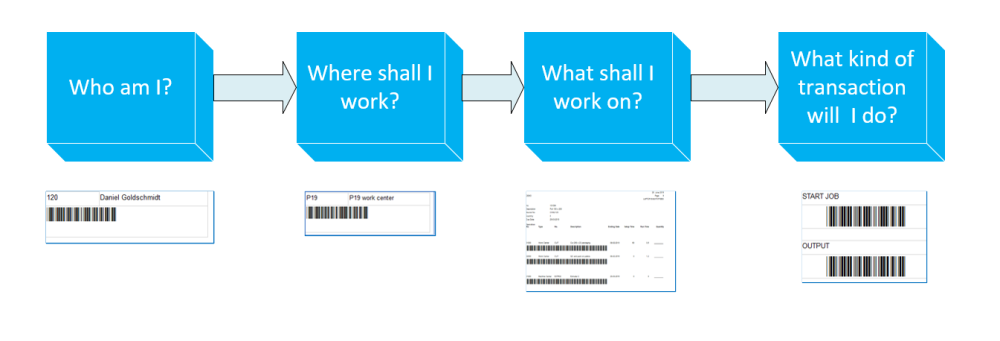

Description of the overall bar code reading principle:

Bar code labels/papers used

1. Employee badges

For every active employee/resource a label can be printed. This label is meant to be kept by the operator.

The employee/resource label is the first step to operate job execution- “I’m Daniel……”

Example:

Scanning the employee badge at the terminal positions the terminal display to the employee:

Note: Employee badges together with absence codes bar codes can be used in the Naveksa Time/Attendance module also.

2. Work center / Machine center / Resource badges

For every active work center/machine center/resource a label can be printed. This label – one or more, is meant to be placed in convenient places in the work center, machine center or at the resource.

This label is the used as the next step to identify the resource to be worked at. So “I’m Daniel – I want to work at the 100 Assembly work center”

Example:

Scanning the resource will position the terminal display to this value:

3. Production Order Routing sheet

When releasing a production order in standard NAV/365 BC a routing sheet is automatically printed for each production line order if the order contains more than one line.

The routing sheet is meant to follow the order.

If needed, the production order routing sheet can be re-printed using the ShopFloor planning function.

The operator scans the desired production order routing line which will position the terminal display to this value on the display and high-light the line.

4. Transaction codes

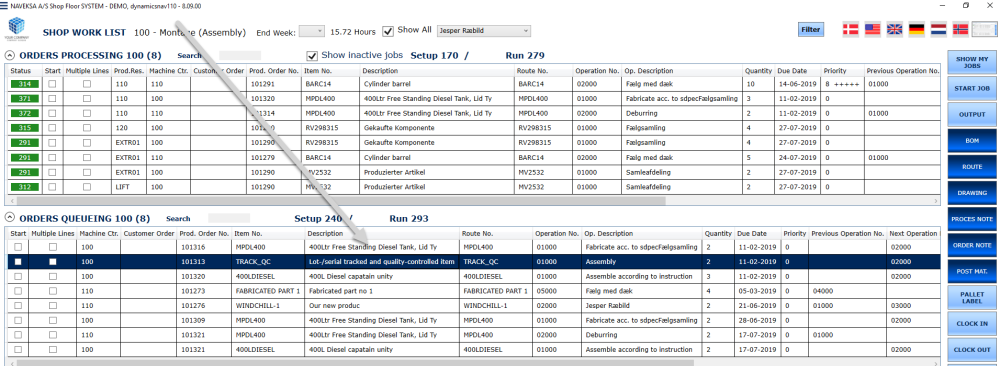

Transaction codes are all the possible transactions that can be scanned and applied on a production order, and replaces the use of the terminal function buttons.

Standard display functions buttons:

The sheet with transaction bar codes can be printed from the ShopFloor setup.

This transaction codes sheet is meant to be placed close to the individual shop floor terminals, and replaces the need for display screen interactions.

Example:

The transaction list (17 individual transactions) triggers the wanted when scanned:

• Start job, (Triggers the starts of a job for the selected resource)

• Output reporting, (Triggers the standard output display for detailed reporting)

• Output – Setup, (Triggers end of job for a setup operation)

• Output – Part quantity, (Triggers the completion of 1 unit)

• Output – Pause, (Triggers pausing an operation)

• Output – End operation, (Triggers completion/end of job)

• Show BOM, (Triggers the display of the production order bill of material)

• Show Routing, (Triggers the display of the production order routing)

• Show Material shortage, (Triggers the display of current component shortages)

• Show drawing, (Triggers the display of drawings and other documents)

• Show process note, (Triggers the display of routing step process notes, if not automatic)

• Show order note, (Triggers the display of the order comments)

• Material issue, (Triggers production order total component issue)

• Print pallet label, (Triggers the printing of a production order pallet label)

• Print material requisition, (Triggers the printing of a material picking list)

• Print routing sheet, (Triggers the printing of a routing sheet)

• Print job card. (Triggers the printing of the production order routing step job card)

Haben Sie noch weitere Fragen?

NAVEKSA Help desk