Embodied Carbon Scope

Embodied carbon calculations must encompass life cycle stages A1-A5, which includes the energy consumed during construction.

Carbon calculations must reflect the built condition of the project, including any substitutions during construction or otherwise that may have resulted in deviations from design calculations. For the construction phase (A5), teams must include embodied carbon impacts from site activities (A5a) and material waste (A5w). See Resources for the following references on acceptable calculation methods from The Institution of Structural Engineers’ (IStructE) How to Calculate Embodied Carbon and A Brief Guide to Calculating Embodied Carbon.

Approved LCA Tools

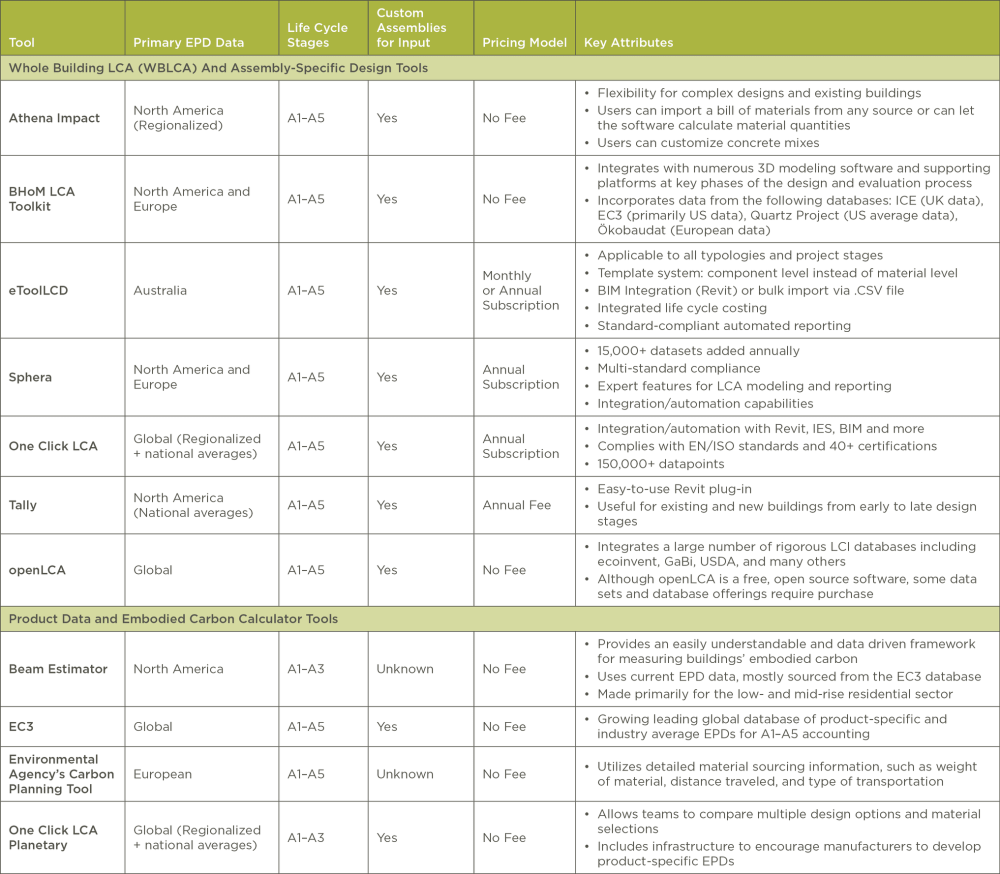

Tools used for whole building carbon analyses and life cycle assessment calculations must have the capability to complete a full upfront carbon (life cycle stages A1–A5) analysis, and calculations must be completed in accordance with ISO 14044. The Institute has approved the tools listed in Table ZC-1 for use by project teams to conduct LCA calculations for buildings, materials, and products. In order to increase industry understanding of the LCA process and facilitate more accurate evaluations, tools that reveal their methodology and encourage data transparency, such as the ones listed below, are preferred.

If a project team uses an approved tool that only encompasses A1–A3, another approved tool must be used to calculate the emissions associated with life cycle stages A4–A5. Project teams are responsible for using the tools appropriately and accurately, reflecting the required level of analysis based on the project type.

For more information about embodied carbon analysis and tool categories, see the “AIA-CLF Embodied Carbon Toolkit for Architects” link in the Resources section.

Table ZC-1 Approved LCA Tools

- Athena Impact Estimator

- BEAM Estimator

- BHoM LCA Toolkit

- Embodied Carbon in Construction Calculator (EC3)

- Environment Agency’s Carbon Planning Tool

- Cerclos (formerly eTool)

- Sphera GaBi

- One Click LCA

- One Click LCA Planetary

- OpenLCA

- Tally

LCA tools continue to develop rapidly, leading to potential discrepancies with this table as changes occur. It is the responsibility of the project team to work with the provider to ensure the tool can do the work required. Project teams may use a different tool that is comparable to at least one of the listed calculators if it is preapproved through a Request for Ruling.

Embodied Carbon Threshold

The embodied carbon threshold (500kg-CO2eq/m2) originates from the Carbon Leadership Forum’s Embodied Carbon Benchmarking Study that analyzed 1,000 building life cycle assessments (LCA’s). The buildings assessed in the study represent a wide range of building types and LCA inputs, yielding a corresponding range of embodied carbon intensities. Consequently, the embodied threshold is attainable for some building types but may be unreasonable for others. All project teams must strive to meet the threshold and document their efforts to reduce embodied carbon, as well as provide a quantitative analysis of the primary drivers of the project’s total embodied carbon.

Environmental Product Declarations and Data Accuracy

Background data used within approved LCA tools may be collected from various sources and databases. Project teams must verify that all information used in an embodied carbon assessment is as accurate as possible for the project in question, prioritizing product-specific and geographically relevant data.

Embodied carbon data should be sourced from Environmental Product Declarations provided by qualified program operators that conduct the EPD development according to ISO Standards on behalf of product manufacturers or industry organizations. All EPDs referenced in calculations must meet the protocols for scope, preparation, and verification as outlined in ISO Standard 14025. ILFI has identified the following EPD databases that project teams can use to search for materials with ISO-approved EPDs:

- EC3

- mindful Materials

- International EPD System

- Sustainable Minds

- UL SPOT

- The EPD Registry

- Eco Platform

- Institut Bauen und Umwelt e.V.

All EPDs referenced must be current at the time of product specification. Project teams must strive to utilize EPDs that are product-specific whenever possible.

When only industry-average EPDs are available, project teams are encouraged to request or advocate for product-specific data directly from manufacturers. For products without EPDs, teams should use reasonably equivalent products based on material characteristics (in terms of raw materials, transport, and manufacturing processes), sourcing, and performance to devise baseline and design case global warming impacts. Teams must provide descriptions for their reasoning and advocate to manufacturers for product-specific data. See Resources for a link to a sample advocacy letter.

Reference Study Period

(Section previously titled Lifespan, relocated from Embodied Carbon Offset Clarifications)

Projects including biogenic carbon sequestration claims in their A1-A5 emissions must use a standard 60-year reference study period when calculating embodied carbon for reporting consistency and industry alignment, and as best practice to ensure buildings with longer life spans are not penalized for the carbon impacts of replacing materials over time. Projects reporting A1-A5 emissions without the inclusion of biogenic carbon sequestration claims do not need to report their reference study year.